Suradech14 / iStock / Getty Images Plus via Getty Images

Coloring Our Future Lead-Free

Photo courtesy of BASF Colors & Effects.

By Georg Doering, Technical Industry Manager, Pigments for Architectural & Industrial Coatings, BASF Colors & Effects; and Dr. Jana Heiler, Global Commercial Industry Manager, Pigments for Architectural & Industrial Coatings, BASF Colors & Effects, Ludwigshafen am Rhein, Germany

Due to their brilliant colors, their universal performance and their reasonable price, lead chromate pigments have been used in various applications for many decades. However, studies conducted for many years have already proven that these products may cause cancer, may damage the unborn child, are suspected of damaging fertility and harm the environment. Today these concerns are widely known, and lead chromate pigments have been banned from several applications in the North American and European markets. This first wave of governmental legislations and official market bans has been successfully implemented; however, to-date many countries in Asia, Africa and South America have resisted implementing an official ban on lead chromate pigments.

In October 2020, the Strategic Approach to International Chemicals Management (SAICM), whose secretariat is hosted by the United Nations Environment Programme (UNEP), has published a Policy Brief that reminded us about the global situation in lead paint, and called for a fast realization of its global elimination. Pointing out the burden of disease due to lead exposure and its threats to both aquatic and terrestrial ecosystems, the SAICM Policy Brief forms a call to action for more political guidance.¹

Photo courtesy of BASF Colors & Effects.

With the campaign “Color our Future Lead Free,” BASF's Colors & Effects® brand supports the industry with a designated lead-free portfolio and provides paint manufacturers with reformulation guidance. Thanks to the proactive education and close collaboration with manufacturers, the global paint and coatings market is well prepared for the second wave of lead chromate replacement that has already started and may soon be sped up due to upcoming regulations in African, Asian and South American countries.

This article highlights the challenges of lead replacement. It also shows how modern pigment developments provide an alternative to lead chromate in all coatings applications, and how the performance of lead-free formulations can be improved. New hybrid pigment technologies support paint and coating manufacturers with this change. Through optimizing the value-in-use with individualized coloration, performance and cost balance of existing lead-free formulations can be improved.

The Basis of Successful Lead Chromate Replacement

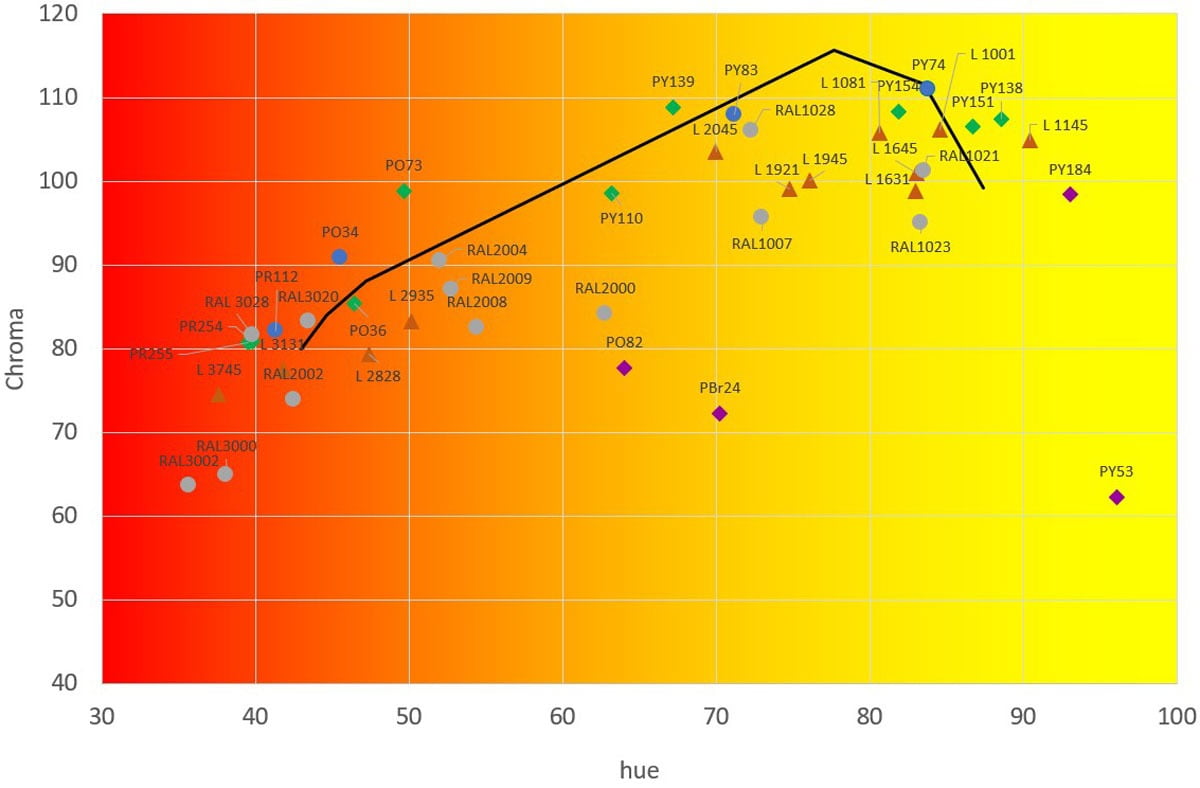

Figure 1 shows the color space coverage of lead chromate pigments. While the black line indicates the possible chroma range, the grey dots show the relevant RAL shades in the red to yellow color space that were formerly created with lead chromate pigments. The set of highly chromatic low-performance pigments (shown in Figure 1 as blue circles) and high-performance organic pigments (green diamond shapes) form the basis to reach, and sometimes even to extend, the color space without using lead chromate products. However, the balance of matching highly chromatic shades that give the desired durability in demanding coating systems remains a challenge. For this reason, modern hybrid pigments have been created that make use of the less chromatic inorganic products (violet diamond shapes) to enable the required performance, such as high fastness and opacity.

FIGURE 1 ǀ Range of yellow to red color space, showing the color positioning and chroma of relevant RAL shades and various lead-free pigment alternatives in relation to the color space coverage with lead pigments.

In order to enable paint manufacturers to eliminate lead chromate within their products, it is crucial to provide alternatives that meet the demands of the industry. Each application has different color and performance requirements, which can be realized with a pigment portfolio that is specialized for lead chromate replacement. The basis for targeting specific shades with tight color specifications are the broad color space coverage and high chroma. In addition, the chemical fastness and dispersibility of the pigment can be crucial within production. Furthermore, temperature stability and opacity support the application process, while weather fastness ensures long-lasting color and prevents chalking.

Since lead-free pigments provide a range of properties in terms of coloristic behavior, performance and price level, a variety of lead-free alternatives is required for an industry with such diverse applications. While pigments for exterior paints need to be durable in terms of color retention and weathering, interior products, which don’t need such resistance against weather conditions, still require a reasonable light fastness. Applications like coil, powder coatings or road marking require pigments with good heat resistance. Matching corporate colors comes with the challenge of providing low metamerism.

Balancing these targets of best color fit, required performance parameters and the most economical solution, it is recommended to match the final shade with lead-free pigments in a tailored formulation for the specific application instead of just replacing the lead chromate pigment. As a reformulation usually proves to be the best approach, reformulation guidance is a crucial part in the process of supporting paint manufacturers with banning lead chromate from their products.

The Impact of Various Lead-Free Formulations

The three examples of possible formulations for RAL 1007 in Table 1 showcase the impact coatings manufacturers have with the variety of available lead-free pigment alternatives.

TABLE 1 ǀ One lead-based formulation and three lead-free formulation alternatives with various optimization targets for a RAL 1007 shade.

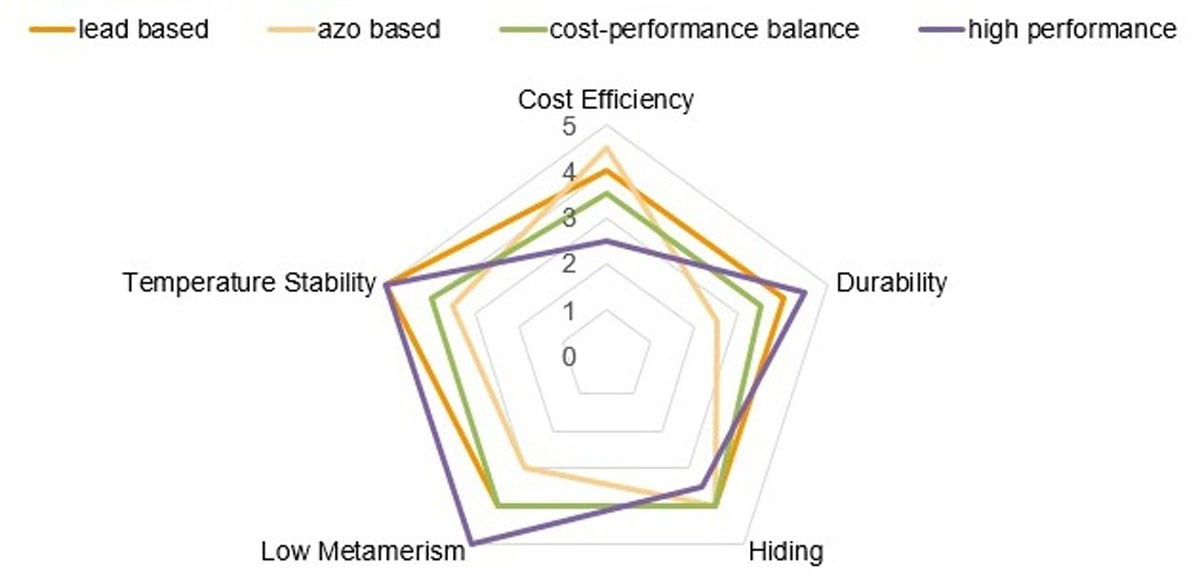

The performance comparison of the three different formulation alternatives with a lead-based RAL 1007 shade is displayed in Figure 2. The original lead-based formulation comes with strong performance attributes in terms of durability, hiding and low metamerism, while providing good cost efficiency and high temperature stability. The comparison shows the spectrum of customized possibilities with lead-free alternatives. Depending on the individual requirements of the targeted application, and on the amount of available pigment alternatives, the attributes of the lead chromate formulation can be met and often exceeded.

FIGURE 2 ǀ Comparison of three different formulation alternatives for a lead-based RAL 1007 shade in terms of cost efficiency, durability, hiding, metamerism and temperature stability.

While the cost-performance balanced formulation in Figure 2 indicates the challenge of meeting the performance attributes of lead chromate-based pigments with a comparable cost level, the low-performance formulation, which is based on azo chemistry, shows an easy lead chromate replacement with lower cost, compromising on performance and coloristic properties. In addition, the high-performance formulation indicates how new pigment developments allow specific attributes to be pushed and tailored to the requirements of the targeted application.

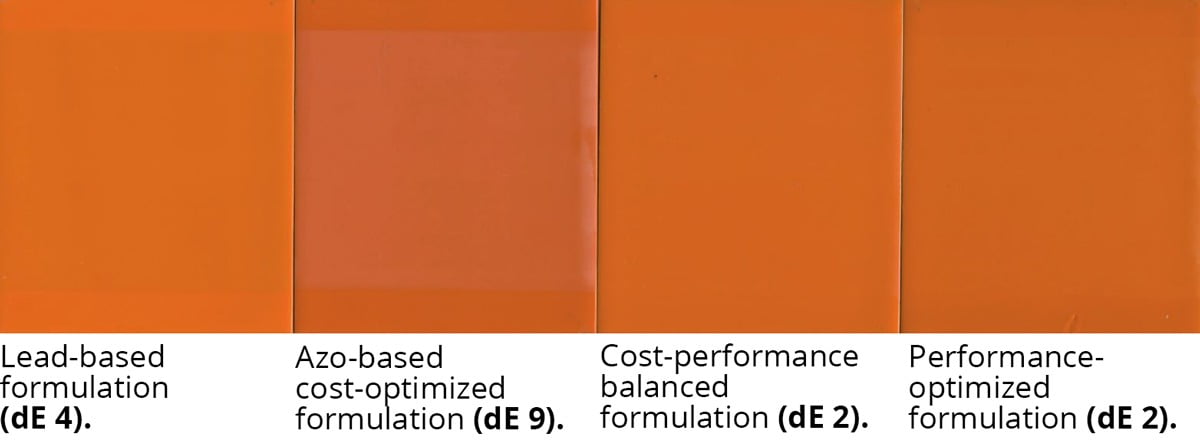

The coloristic improvements with lead chromate-free pigments also take into consideration the lightfastness of coatings. As Figure 3 shows, both the performance-optimized as well as the cost-performance balanced formulation don’t show any noticeable color shift after a 2,000-hr Xenotest. In comparison, the coating with the lead-based formulation has changed into the typical darker orange shade, while the azo-based formulation shows a color fade out.

FIGURE 3 ǀ 2,000-hr Xenotest for three different formulation alternatives in comparison to a lead-based RAL 1007 shade.

Hybrid Pigment Technologies Push the Limits

Organic pigments usually offer high color strength and chroma, but their opacity and fastness properties show limitations. Conversely, inorganic pigments offer high fastness and opacity, whereas color strength and chromaticity are lower. Hybrid pigment technologies combine the best attributes of inorganic and organic components, allowing to match the lead chromate-free RAL shades to the various industries’ demands. Covering the complete red to yellow color space, the hybrid Paliotan® pigment family has been developed to enable the best balance in terms of chroma, opacity and durability. While the technology results in superior hiding power and rheology compared to organic pigments, the chroma has been increased significantly in comparison to inorganic alternatives in the same color space.

The new hybrid pigment technology of Pacific Orange L 2828 has provided the market with formulation flexibility for powder coatings with high weather fastness requirements. It finally enables formulations with Pigment Red 254 without an unwanted brownish color shift. With its high chroma, this opaque powder pigment even expands the orange color space. Thanks to using the most beneficial properties of organic and inorganic components, the orange hybrid enables lead-free and highly chromatic orange shades in demanding powder coatings. Compared to other high-performing orange pigments, the hybrid offers outstanding weather resistance and good opacity in addition to high temperature and superior chemical resistance.

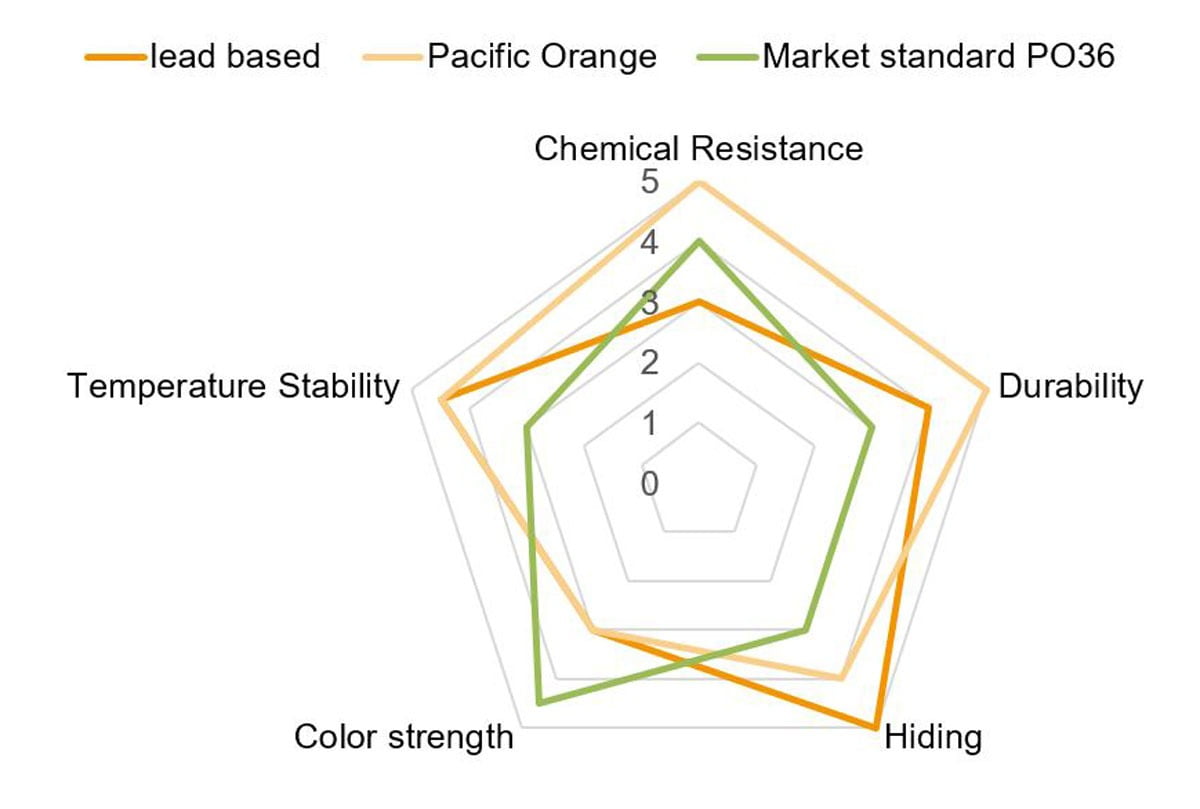

As shown in Figure 4, the hybrid technology outperforms the lead-based formulation in these performance attributes. In addition, the comparison with a lead-free powder coating formulation based on a market standard Pigment Orange 36 highlights the hybrid’s potential for applications with high-performance requirements.

FIGURE 4 ǀ Performance balance of Pacific Orange pigment compared to a formulation with a market standard lead-free Pigment Orange 36 and the former lead-based formulation.

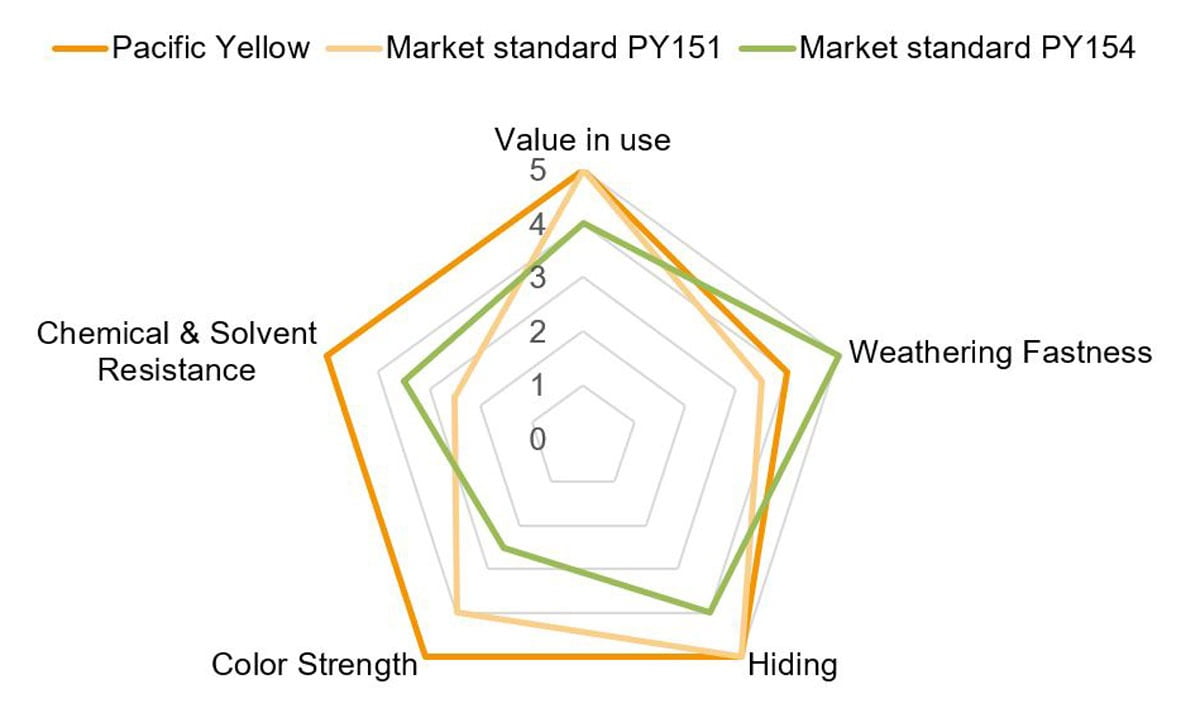

Especially developed to foster further lead-chromate replacement for the Asian market, hybrid pigment technologies push the limits in solvent- and water-based systems. With hybrid technology, coatings manufacturers can increase the performance level compared to the lead-free market standards Pigment Yellow 151 and 154, and optimize the formulation properties according to the specific requirements of the end application.

FIGURE 5 ǀ Performance balance of Pacific Yellow hybrid pigments compared to a formulation with market standard lead-free Pigment Yellow 151 and 154.

As shown in Figure 5, the hybrid pigment technology of Pacific Yellow L 1001 and 1081 enables the formulation of the brightest yellows with extreme brilliance that provide excellent opacity, chemical and solvent resistance, as well as the best value in use. The comparison with the market standard lead-free Pigment Yellows 151 and 154 demonstrates the improvements of the new pigment technology.

While hybrid pigments can be adjusted in color, opacity and color strength to match the former results of lead chromate formulations, the durability in hybrid pigment at masstone can also be adjusted through the smart combinations of organic and inorganic components. If required, a completely customized hybrid pigment can be produced that is tailored to the specific requirements of a coatings manufacturer.

Industry Engagement and Political Guidance for a Lead-Free Future

A broad portfolio of lead-free pigment alternatives in combination with sound formulation expertise enable paint manufacturers around the world to shift to lead-free paint and to improve their products in the yellow to red color space. The new high-performing hybrid pigment technologies enable the evolution of lead-free paint and coatings for manufacturers aiming to improve their already established lead-free formulations. Hybrid pigments can be adjusted in color, opacity and color strength to match the properties that lead chromate pigments provided in the past. The data shows that modern pigment technologies can even outperform the former lead-based formulations. Joining forces with industry partners, pigment producers have invested in the development of these pigments to enable not only a replacement, but a better alternative to lead chromate-based products. With the start of the second wave of lead chromate replacement, global paint companies benefit from the already existing reformulation expertise. Supported by laws to phase-out lead in paint, the industry could now manage the shift to sustainable solutions with higher speed within a fair environment for paint manufacturers that invest in coloring our future lead free.

If you are looking for more information about pigment alternatives for lead-free formulations, visit www.colors-effects.com/sustainability/color-our-future-lead-free.

References

¹ SAICM Policy Brief: Eliminating Lead Paint: The Role of the Paint Industry. October 2020, https://saicmknowledge.org/library/eliminating-lead-paint-role-paint-industry (25.11.2020).