Ready to proof -- CLJ 1/17/22

Proofed by KP 1-18-22

Proofed by KJ 1/18

INDUSTRY UPDATES

Metals are typically good conductors of electricity and heat. In 2017, Wu and his research team discovered that electrons in vanadium dioxide behave like a metal to electricity but an insulator to heat — in other words, they conduct electricity well without conducting much heat. “This behavior contrasts with most other metals where electrons conduct heat and electricity proportionally,” Wu explained.

Vanadium dioxide below about 67 °C (153 °F) is also transparent to (and hence not absorptive of) thermal-infrared light. But once vanadium dioxide reaches 67 °C, it switches to a metal state, becoming absorptive of thermal-infrared light. This ability to switch from one phase to another — in this case, from an insulator to a metal — is characteristic of what’s known as a phase-change material.

To see how vanadium dioxide would perform in a roof system, Wu and his team engineered a 2-cm by 2-cm TARC thin-film device. TARC “looks like Scotch tape, and can be affixed to a solid surface like a rooftop,” Wu said.

In a key experiment, co-lead author Kechao Tang set up a rooftop experiment at Wu’s East Bay home last summer to demonstrate the technology’s viability in a real-world environment. A wireless measurement device set up on Wu’s balcony continuously recorded responses to changes in direct sunlight and outdoor temperature from a TARC sample, a commercial dark roof sample, and a commercial white roof sample over multiple days. The researchers then used data from the experiment to simulate how TARC would perform year-round in cities representing 15 different climate zones across the continental United States.

Wu enlisted Ronnen Levinson, a co-author on the study who is a staff scientist and leader of the Heat Island Group in Berkeley Lab’s Energy Technologies Area, to help refine the model of roof surface temperature. Levinson developed a method to estimate TARC energy savings from a set of more than 100,000 building energy simulations that the Heat Island Group previously performed to evaluate the benefits of cool roofs and cool walls across the United States. Finnegan Reichertz, a 12th grade student at the East Bay Innovation Academy in Oakland who worked remotely as a summer intern for Wu last year, helped to simulate how TARC and the other roof materials would perform at specific times and on specific days throughout the year for each of the 15 cities or climate zones the researchers studied for the paper.

The researchers found that TARC outperforms existing roof coatings for energy saving in 12 of the 15 climate zones, particularly in regions with wide temperature variations between day and night, such as the San Francisco Bay Area, or between winter and summer, such as New York City. “With TARC installed, the average household in the U.S. could save up to 10% electricity,” said Tang, who was a postdoctoral researcher in the Wu lab at the time of the study. He is now an assistant professor at Peking University in Beijing, China.

Standard cool roofs have high solar reflectance and high thermal emittance (the ability to release heat by emitting thermal-infrared radiation), even in cool weather. According to the researchers’ measurements, TARC reflects around 75% of sunlight year-round, but its thermal emittance is high (about 90%) when the ambient temperature is warm (above 25 °C or 77 °F), promoting heat loss to the sky. In cooler weather, TARC’s thermal emittance automatically switches to low, helping to retain heat from solar absorption and indoor heating, Levinson said.

Findings from infrared spectroscopy experiments using advanced tools at Berkeley Lab’s Molecular Foundry validated the simulations. “Simple physics predicted TARC would work, but we were surprised it would work so well,” said Wu. “We originally thought the switch from warming to cooling wouldn’t be so dramatic. Our simulations, outdoor experiments and lab experiments proved otherwise — it’s really exciting.”

The researchers plan to develop TARC prototypes on a larger scale to further test its performance as a practical roof coating. Wu said that TARC may also have potential as a thermally protective coating to prolong battery life in smartphones and laptops, and shield satellites and cars from extremely high or low temperatures. It could also be used to make temperature-regulating fabric for tents, greenhouse coverings, and even hats and jackets.

BERKELEY, CA – Scientists have developed an all-season smart-roof coating that keeps homes warm during the winter and cool during the summer without consuming natural gas or electricity. Research findings reported in the journal Science point to a groundbreaking technology that outperforms commercial cool-roof systems in energy savings.

“Our all-season roof coating automatically switches from keeping you cool to warm, depending on outdoor air temperature. This is energy-free, emission-free air conditioning and heating, all in one device,” said Junqiao Wu, a faculty scientist in Berkeley Lab’s Materials Sciences Division, and a UC Berkeley professor of materials science and engineering who led the study.

Today’s cool-roof systems, such as reflective coatings, membranes, shingles or tiles, have light-colored or darker, “cool-colored” surfaces that cool homes by reflecting sunlight. These systems also emit some of the absorbed solar heat as thermal-infrared radiation; in this natural process known as radiative cooling, thermal-infrared light is radiated away from the surface.

The problem with many cool-roof systems currently on the market is that they continue to radiate heat in the winter, which drives up heating costs, Wu explained. “Our new material — called a temperature-adaptive radiative coating or TARC — can enable energy savings by automatically turning off the radiative cooling in the winter, overcoming the problem of overcooling,” he said.

Scientists Develop Smart-Roof Coating That Provides Year-Round Energy Savings

Samples of the temperature-adaptive radiative coating. Credit: Thor Swift/Berkeley Lab.

Upcoming EU Chemical Legislation Will Create Challenges for Europe’s Adhesives, Coatings and Sealants Industries

BRUSSELS – The European Chemical Industry Council (Cefic) is reporting that industry leaders recently called on the European Commission to work together to develop an EU Chemical Industry Transition Pathway to sustain the massive investments required to meet the objectives of the EU Green Deal. The action followed the release by European Cefic of the first in a series of studies, conducted by independent economic research consultancy Ricardo Energy & Environment, on the business impacts of the EU Chemicals Strategy for Sustainability (CSS). The data from more than 100 European chemical companies will be used as an input to the European Commission’s impact assessments on the Classification, Packaging and Labelling Regulation (CLP), and REACH, the centerpieces of EU chemical legislation.

According to this first study, as many as 12,000 substances could potentially be in the scope of the two upcoming legislative proposals alone — the changes to CLP and the application of a Generic Risk Approach. The study found that these substances could cover up to 43% of the European chemical industry’s total turnover.

Image courtesy of The European Chemical Industry Council.

After applying different weighting factors to account for uncertainty about definitions and criteria in the CSS, the consultants concluded that the most likely impacted portfolio would be as much as 28% of the industry’s estimated turnover. The companies consulted indicated that around one third of this most likely affected portfolio of 28% could potentially be substituted or reformulated. However, the ability of companies to substitute potentially affected products will largely depend on the details of the upcoming regulations, on what might be technically and economically feasible, and especially on how customers will react to the substitutes or reformulated products. Among the most significantly impacted downstream sectors are adhesives, sealants and paints.

Dr. Martin Brudermueller, Cefic President, said, “The role of the chemical industry is to supply downstream customers with crucial materials to meet the targets of the Green Deal. The EU chemicals industry is a major supplier of all manufacturing industries, and essential and strategic value chains, including pharmaceuticals, electronics, EV batteries, construction materials. The intended policy changes coming with CSS will also create a significant ‘ripple effect’ across many value chains relying on chemicals.”

The economic analysis concluded that even when derogations are taken into account, a heavy net impact remains. Regardless of the scenario considered, this would represent a net market loss of at least 12% of the industry’s portfolio by 2040, according to the study. As only two of the measures proposed by the CSS have been assessed so far, the cumulative impact of all other changes proposed by the strategy will be bigger. The effect that these changes could have on EU chemical exports has not been examined, which could add significantly to the overall impact.

Brudermueller explained, “The chemical industry has always been driven by innovation, passion for new technologies and entrepreneurial spirit. The results of this study indicate that there could be an opportunity for an industry-wide substitution effort to deliver on the goals of the Chemicals Strategy for Sustainability. However, there is a lot of uncertainty as to how businesses along the value chain could achieve it under the current framework. Industry needs a predictable growth framework for economic investments in the coming two decades. For us to meet the many challenges of the Green Deal, we need a robust Chemical Industry Transition Pathway.”

The proposed Transition Pathway should include timelines and measures for the industry to develop substitutes and focus on those products where these substitutes could be available first. In this, it should build on proven and established approaches such as the risk assessment under REACH. Incentives will be needed to create markets for these new chemicals, combined with a doubling down on enforcement of REACH and product safety legislation for imports. The package should be complemented by a strong innovation agenda to accelerate the development of safe and sustainable-by-design alternatives. Finally, the Transition Pathway should also address the other three transitions that the chemical industry has to undergo — climate neutrality, digitalization and circularity. The next report is expected to be published in the second quarter of 2022.

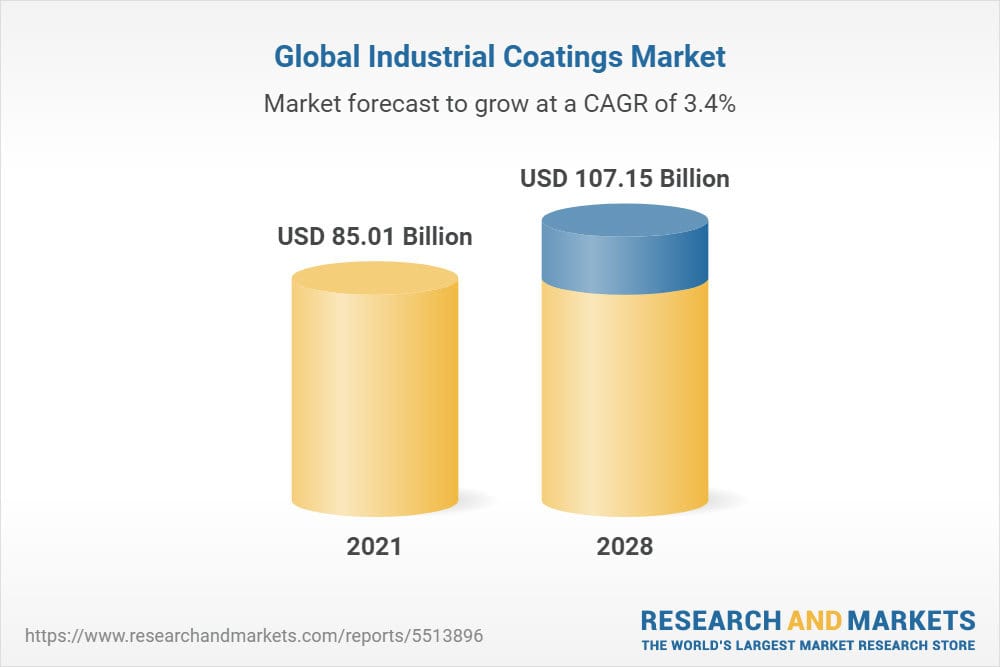

New Report Predicts Growth in Global Industrial Coatings Market

DUBLIN – Market research store Research and Markets is offering a new study that predicts the global industrial coatings market will reach $107.15 billion by 2028. According to the report, the market is expected to expand at a compound annual growth rate of 3.4% from 2021 to 2028. Demand for eco-friendly industrial coatings is being driven by a rise in consumer awareness regarding sustainable products and increasingly stringent environmental regulations around the reduction of VOC emissions. Government regulations addressing the environment, especially air pollution, in the United States, China and the countries of Western Europe will continue to be a driving factor for the adoption of low-pollution coating technologies in the coming years.

The report predicts that the electronics end-use segment will witness significant growth over the forecast period. Industrial coatings are used in various electronic applications such as tablets, PCs, smartphones, touch displays and wearable devices. Industrial coatings help improve the efficiency of electronic products and provide durability, design, color and advanced functionality such as anti-fingerprint, anti-smudge, anti-glare, and low reflective for touch and display screens. According to the report, robust growth is expected in the electronics industry in Asia-Pacific. This growth is due in part to the presence of various electronic goods producers and a versatile manufacturing landscape, which includes support from governments, availability of raw materials and cheap labor. These factors are expected to impact the demand for industrial coatings in the electronics industry.

In terms of revenue, the study found that the general industrial end-use segment accounted for the largest revenue share in 2020 and is expected to witness prominent growth over the forecast period. Asia-Pacific dominated the market in 2020 and is expected to maintain its lead from 2021 to 2028. Additionally, the acrylic product segment is potentially fueling market growth due to its rising demand in various end-use industries

Regulations have led to a shift in demand from solvent-based coatings to low-VOC or eco-friendly products, such as powder coatings and water-based and UV-curable coatings. These low-VOC products contain fewer solvents that evaporate during the application phase and help in achieving a greener environment with minimum VOC emissions. Companies are increasingly focusing on the development of low-VOC content and sustainable solutions for customers across all industry sectors.

Image courtesy of Research and Markets.

Philippine NGO Finds Excessive Lead Levels in Imported Spray Paints

QUEZON CITY, Philippines – According to the watchdog group EcoWaste Coalition, paint products in aerosol cans containing significant levels of lead are still offered for sale by offline and online retailers in the Philippines despite the ban on such paints. The group made this revelation as the Chemical Control Order (CCO) phasing out lead in all paint categories in the country marked its eight anniversary.

Put into effect in 2013, the CCO issued by the Philippines Department of Environment and Natural Resources stipulates a maximum limit of 90 parts per million (ppm) for lead in paint, and set a three-year period (2013-2016) to phase-out leaded decorative paints and a longer six-year period (2013-2019) for leaded industrial paints. Both the EcoWaste Coalition and the International Pollutants Elimination Network contributed to the development of the CCO. These organizations have been conducting lead paint studies and providing public information and policy advocacy activities in pursuit of the country’s shift to non-lead paint production backed by the Philippine Association of Paint Manufacturers (PAPM).

For its latest lead paint investigation, the EcoWaste Coalition in October and November 2021 procured a total of 60 spray paints representing 16 brands that were obtained from online dealers and from various retail stores in 11 cities in the Philippines, including Angeles, Antipolo, Batangas, Calamba, Lucena, Mabalacat, Malolos, Manila, Paranaque, San Fernando, and San Jose del Monte. The samples were mostly imported from China and Thailand.

The sampled products are often labeled as ideal for almost all types of surfaces and painting applications, and can be used to touch up scratches or spruce up metal items, as well as a material for school projects. The samples were initially screened for lead through a handheld X-Ray Fluorescence (XRF) analyzer. The 37 samples that exceeded the 90 ppm limit were subsequently submitted to SGS, a private testing company, for a total lead content analysis performed by inductively coupled plasma — optical emission spectrometry.

Laboratory test results confirmed that the 37 samples — representing 11 brands — contained lead concentrations up to 97,100 ppm. Of the 37 samples, 30 had extremely high lead concentrations in excess of 10,000 ppm, and of these 30 samples, 23 had lead above 40,000 ppm. The remaining seven samples had lead levels between 428 to 4,850 ppm. None of these leaded paints were manufactured by PAPM-affiliated companies.

“Products labeled as ‘lead free’ when they are not give consumers a false assurance about a product’s lead content. This case of mislabeling points to the importance of third-party certification that will independently confirm compliance to the 90 ppm lead in paint standard,” the groups stated.

Aside from proposing immediate regulatory action, the EcoWaste Coalition reminded consumers to refrain from buying inadequately labeled and uncertified paint products, while urging manufacturers, including those that export paints to the Philippines, to obtain third-party Lead Safe Paint® certification to help consumers in picking paints without lead in excess of the 90 ppm limit.

“We find it very disappointing to find more lead-containing spray paints being sold at retail stores and online shopping sites in violation of the CCO. These decorative paints, which are marketed for general use and are accessible to consumers, should have been phased out on December 31, 2016,” said Thony Dizon, Chemical Safety Campaigner, EcoWaste Coalition.

Image courtesy of the EcoWaste Coalition.

New Dates Announced for CHINACOAT

SHANGHAI – The 26th edition of CHINACOAT, originally scheduled for Nov. 16-18, 2021, has been rescheduled to take place March 2-4, 2022. The in-person event will take place at the original venue, Halls E2-E7 of the Shanghai New International Expo Centre (SNIEC). The Online Show was launched on Dec. 15, 2021, and will stay open until March 15, 2022.

Visitors who have registered with real-name authentication to visit the physical show can use the same e-pass/registration notice to attend during the new show date without having to register again. Visitors who have registered to visit the online show can now use the registered e-mail and password to login and start browsing.