Credit: xavierarnau, Vetta, via Getty Images

Partnership Leads to Innovations in Next-Gen Paint Technology

By Eric Stevenson, Director of Product Management, Marketing and Pricing, PPG Architectural Coatings U.S. and Canada; and Scott Torrey, Commercial and Manufacturing Operations Director, Corning Guardiant

Interacting with surfaces is a part of daily life; from touching handrails, light switches, and doorknobs, consistently. With so many points of contact, surfaces can become a breeding ground for harmful microbes. Hygienic maintenance of all spaces has become a top priority for building and facilities managers, as well as homeowners. This attention to maintenance requires a rigorous cleaning routine in public spaces and at home. Which begs the question, what if these high-contact surfaces could clean themselves?

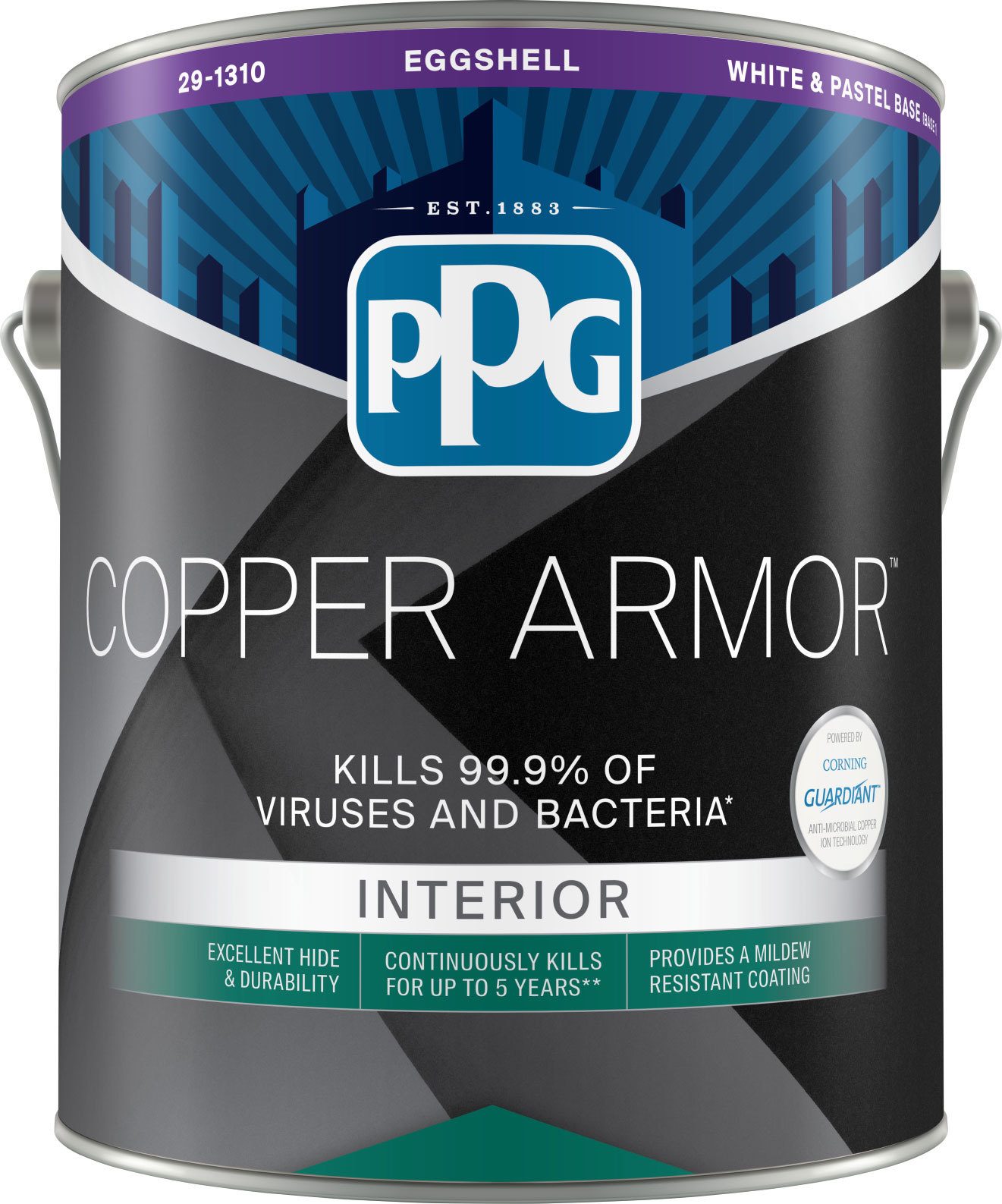

PPG Paints, in collaboration with Corning Incorporated, has worked on an answer to this question. There are now anti-microbial paints that offer continuous protection from harmful bacteria and viruses.

Why is a Glass Company Working in Paint?

In 2012, Corning Incorporated began research and development efforts around anti-microbial materials after the serious illness of a colleague was caused by a hospital-acquired infection. When Corning began researching the issue on a broader scale, the company learned that there was a need for self-sanitizing surfaces.

Corning’s team of researchers had initial success with what became Corning® Guardiant® anti-microbial particles. Corning Guardiant is a copper-based anti-microbial additive that enables paints and other materials to have the microbe-killing potency of copper without being limited by metallic copper’s look and feel. While the team was able to demonstrate proof of concept with incorporating the additive into paint, they quickly realized that they would need to work with an industry leader in the business to bring a viable application to market.

Corning employees in a paint lab.

“We were introduced to PPG, who has many similarities to Corning including a long history of success in innovation,” said Dr. Joydeep Lahiri, division vice president and program director, Specialty Surfaces, Corning Incorporated. “We were thrilled to begin partnering with PPG on a multi-year journey working to create a virucidal coatings category in the U.S.”

Journey to EPA Registration

Prior to 2020, the U.S. Environmental Protection Agency (EPA) only permitted virucidal efficacy claims on liquid disinfectant products. From 2016 to 2020, Corning and PPG had several interactions with the U.S. EPA in which they showcased the need for products with built-in virucidal efficacy in addition to bactericidal efficacy, which required the development of a test method for measuring viral kill. After several years of collaboration in this area, in October 2021, PPG announced the U.S. EPA product registration of their PPG Copper Armor™ paint, powered by Corning’s Guardiant technology.

“Consumers want products that offer multiple barriers from harmful bacteria and viruses that live on the surfaces they’re exposed to on a daily basis,” said Brian Osterried, senior portfolio manager and technical lead of PPG Copper Armor. “PPG’s Copper Armor is the first paint product to provide a barrier against harmful microbes on walls, trims, and doors, and we’re excited that our partnership with Corning made this product possible.”

How Does it Work?

As a naturally occurring material, copper has been utilized for centuries for its anti-microbial properties that are effective in protecting against a broad spectrum of bacteria and viruses, including microbes, which can persist on surfaces for long periods. Copper is also effective against antibiotic-resistant strains and minimizes concerns about exacerbating anti-microbial resistance. In addition, these anti-microbial properties come along with the benefit of a favorable toxicological profile relative to many chemical biocides.

Glass is the key ingredient that unlocks the anti-microbial power of copper. Corning’s Guardiant technology is a special glass ceramic that stabilizes the most bioactive form of copper ions and releases them over time to enable surfaces that are continuously protected from harmful bacteria and viruses.

An added benefit of this interior paint is that consumers do not face a trade-off of product performance or a diverse color palette. Copper Armor is available in more than 600 colors from the PPG palette, and in multiple finishes, including eggshell, satin, and semi-gloss.

“Other than its exceptional germ-killing properties, Copper Armor offers similar performance benefits of other premium paint,” Brian said. “It’s similar in price range, used for the same applications, and available in multiple sheens and colors.”

Where is the Paint Used?

Copper Armor is a versatile coating formulation that can be used in a variety of environments. It is also well suited for application in high-traffic areas such as health care, hospitality, office, and educational environments, as well as residential applications. PPG’s Copper Armor paint with Corning Guardiant technology continuously kills viruses and bacteria within two hours of contact with the painted surface for up to five years, providing a barrier against harmful microbes on walls, trim, and doors. It is also effective at resisting mold and mildew.

The product was recently used as part of an anti-bacterial and anti-viral renovation project in the Northside Independent School District (NISD), located in San Antonio, Texas. As a result of the COVID-19 pandemic, NISD experienced high rates of absenteeism among students and faculty. To add an extra barrier against bacteria and viruses in the building, and make students and staff feel comfortable returning to school, the district applied the coating to high-traffic areas, such as nurses’ offices and hallways in the building.

PPG’s health- and eco-friendly coating provides an anti-bacterial and anti-viral barrier on surfaces and peace of mind for NISD students, faculty, and staff without having to repaint the surfaces for several years. The coating is also environmentally friendly, thanks to its low-odor and zero-VOC characteristics.

Recently, PPG’s Copper Armor has received registration from the U.S. EPA as well as 46 states, and earned the prestigious 2022 R&D® 100 Award for anti-microbial, anti-viral paints.

To learn more about PPG Copper Armor paint and to find a store near you, visit: www.ppgpaints.com/copper-armor-paint.

*Images courtesy of Corning Incoprporated and PPG Paint.