Ready to proof -- Clare 12/7/21

KJ proofed and sent correction to Clare on 12/9

Revised on 12/9

Ready for author

Photo: TPAP8228, iStock/Getty Images Plus, via Getty Images

Five Disasters

Caused By Corrosion

By Samuel Cowlishaw, Marketing Manager, Blend Supply, Fort Worth, TX

The industrial coatings contractors that we partner with across the country do important work. When something goes wrong, there are lives at stake. Whether it is painting the structural steel inside buildings, trailers or earth-moving equipment, making sure that corrosion does not sneak in is a high priority. Our infrastructure ultimately depends on paint, and as a coatings supplier we do not take that lightly.

This article will review five disasters caused by corrosion. Corrosion being defined as, "when a refined metal is naturally converted to a more stable form such as its oxide, hydroxide or sulphide state, this leads to deterioration of the material." When corrosion (rust) attacks your metal, the structural integrity will eventually fail. This can lead to injuries and even death. Some global examples follow.

Genoa, Italy Bridge Collapse

In August of 2018, a bridge collapsed in Italy, resulting in the death of 43 people. The bridge was only 51 years old, and was frequently used by local citizens. The steel cables supporting the bridge failed due to damage from corrosion.

“Italian engineering experts have heavy suspicions that corrosion to the bridge's steel cables contributed to the collapse, saying that it decreased the bridge's overall strength by 20%.” Global Resilience Institute at Northeastern University

Sinking of the Erika

In December of 1999, a Maltese tanker broke in two while traveling near the coast of Brittany, France. Nearly 19,800 tons of oil were spilled. There were multiple parts of the ship that had failed due to corrosion, and the final straw that broke it apart was severe weather. There were immense economic and environmental consequences for the region.

"In an inspection in Portland in July 1994, holes were discovered in the main deck coaming, indicating that signs of corrosion were already in place more than five years before. It was also found that there were holes in both the portside and starboard inert gas system risers, which are critical items of safety equipment...There was yet more evidence of corrosion, with the ship's watertight doors not sealing properly and wasting on the door coamings." Corrosion Doctors

Fall of Railway Traffic Lights

In November of 2014, a train travelling through England struck the railway traffic lights that had fallennear an intersection. The post holding the lights fell due to corrosion at its base and was then struck by an oncoming train. Corrosion ate through the pole, causing it to fall and ultimately resulting in the entire track being blocked.

"The Rail Accident Investigation Branch said the outcome could have been much more serious if the first train to encounter the collapsed signal had been travelling at speed on the completely obstructed track. It found the hollow steel post had corroded just above ground level, but could not be seen because it was hidden by ballast." BBC

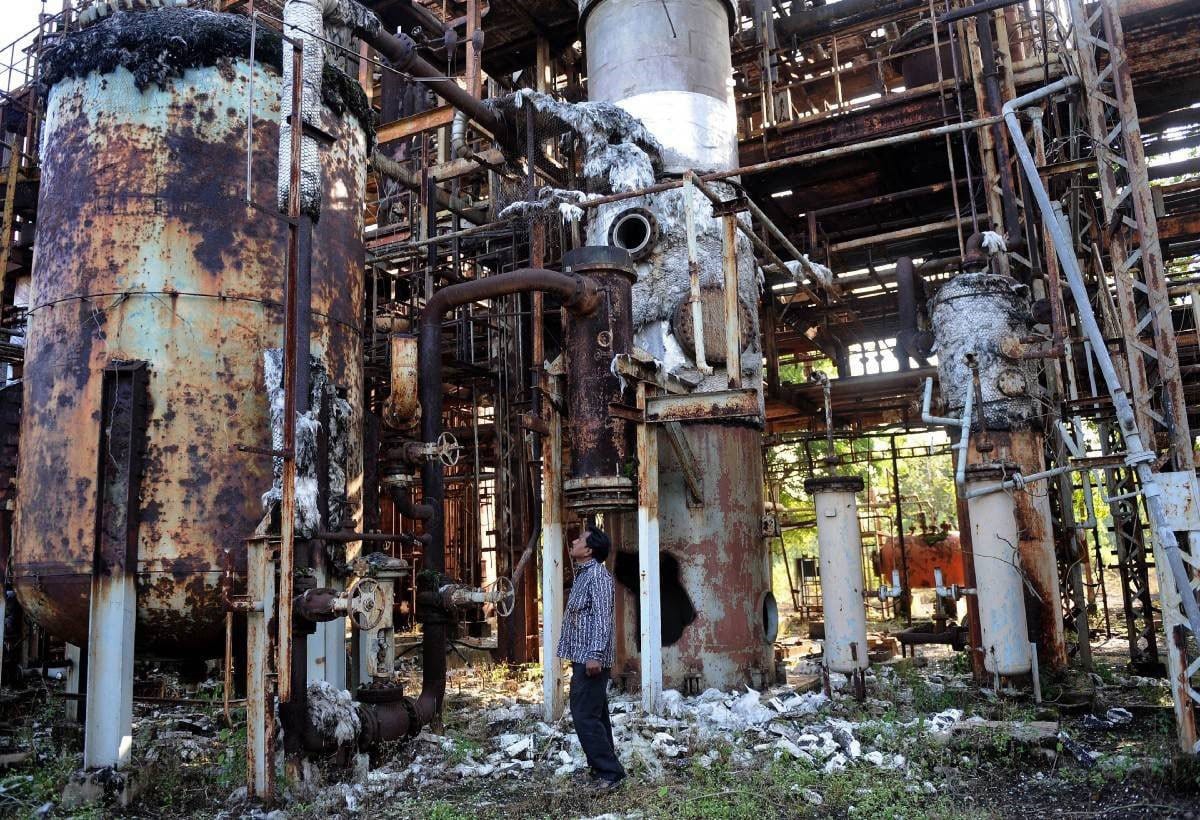

Bhopal, India Incident

In December of 1984, one of the world's largest industrial disasters occurred, resulting in the death of nearly 8,000 people. Corrosion caused toxic gas (phosgene, monomethyl amine (MMA), methyl isocynate (MIC) and the pesticide carbaryl, known as Sevin) from a pesticide plant to leak into the atmosphere.

"In the night between 2 and 3 December 1984, there was a penetration of large amounts of water into the tank with methyl isocyanate (MIC), with over 40 tons of MIC. The addition of water into the tank caused a runaway chemical reaction, resulting in a rapid rise in pressure and water. Heat generated by the reaction, chloroform concentrations higher than normal and the presence of an iron catalyst caused by the corrosion of the stainless steel tank wall, resulted in the opening of the safety valve... The wind blew the cloud of gas, and more than 500,000 people were exposed to toxic effects of its ingredients...The official death toll is 2,259, while unofficially the number is much higher, about 8,000." Zoran

Balcony Collapse at University of Virginia

In May of 1997, a balcony collapsed during the spring commencement ceremony. This incident killed the grandmother of a medical school graduate and injured 18 people. Though the building was 175 years old, the culprit behind the incident was unseen corrosion. Rust had eaten away at the metal rods inside the balcony, which failed under the weight of the attendees.

"An engineering firm hired by the university said the collapse likely was caused by the failure of one of the four hangar rods that suspended the balcony from the second floor of one of the buildings...The report said that the cast-iron rod, apparently the original from the balcony's construction in the 1820s, corroded over many years, but that a wooden beam hid the damage." The Washington Post

Combating Corrosion

Our recommendation for combatting corrosion is primarily to understand your resin. Resin is the part of the paint that binds all of the coating's ingredients together and makes the paint stick to the substrate. The industrial coatings industry is comprised of four basic resin types (alkyd, acrylic, epoxy, urethane). There are also "modified" versions that combine multiple types. For example, consider Axalta's Tufcote 2.8 HG 3100, which is an acrylic-alkyd. Each resin has strengths and weaknesses, depending on your application. Epoxies tend to have the best corrosion resistance (find out more about their adhesive qualities in my Understanding Epoxy Adhesion article). If you are not mindful of the resin in the paint your shop is using, then structure failures can occur.

Additional considerations are application aspects like surface preparation and application technique. If your coating is unable to adhere to the surface, moisture can sneak in. If the coating is applied too thinly or too thickly, corrosion can occur. Always review the data sheets for the coating you are planning to use before application.

References

1. “Environmental Catastrophe: Sinking of the Erika", Corrosion Doctors.

2. Allen, M; Youssef, N.A. (Washington Post Staff Writers) “Hidden Rust Blamed in Balcony Collapse at U-Va: University Officials Say Corrosion Couldn’t Have Been Caught in Standard Inspections.” The Washington Post (1997): B4–.

3. "Corrosion, Faulty Concrete Suspected In Genoa, Italy Bridge Collapse," Global Resilience Institute at Northeastern University.

4. "Rail Report Finds Corrosion Caused Signal Post to Fall Onto Lines Near Newbury," BBC.

5. The Welding Institute: What Is Corrosion?