Ready to proof -- Niki 12/11

CB proofed 12/12 - left note for Niki on Table 1

KJ proofed on 12/12. A few notes for Niki below.

Ready for author

Photo credit: Egoroff, Creatas Video+ / Getty Images Plus, via Getty Images

Creating Next-Generation Air and Space Coatings in the Modern Age

By Pennie Burnham, Nycote Laboratories

As the aerospace (AS) industry pushes for next-generation surface coating technologies to protect materials exposed to harsh air and space environments, coatings manufacturers dive deep to provide higher-performing coatings. The global aerospace coatings market in 2021 was valued at USD 2.15 billion and is estimated to grow with a CAGR of 5.2% through 2030. Some investment is earmarked for research and development to replace chemicals of high concern, and innovation to support the protection of advanced aerospace materials. This article discusses current and future aerospace coating technologies to protect modern air and spacecraft.

How Do Coatings Protect and Improve Aerospace Material Survivability?

The potential for mechanical functions to be affected by corrosion in aerospace is not a matter of if, but rather when corrosion will impact those functions. To counter the high stakes that aerospace corrosion presents, mission-critical applications require the most innovative, comprehensive, and reliable coating technologies available. Additionally, it is vital to continually invest in developing more high-performing chemical technology as it becomes available.

When aerospace coatings are applied correctly, they are a first line of defense from the elements. These coatings are designed to create a continuous, void-free barrier that keeps substrate materials protected from corrosive media.

Certain AS coatings have specific, critical jobs, for example:

- A conductive lightning strike coating allows the energy from the lightning’s electrical charge to pass through the coating without harming the aircraft; while anti-static coatings provide electronic component protection from static electricity caused by rapid airflow across the surface.

- Primers provide a functional base layer that serves as the anchor point for all subsequent layers of paint and topcoats.

- Specialty coatings provide customized protection that resists the corrosive effects of service chemicals like hydraulic fluids, jet fuel, and aircraft de-icers.

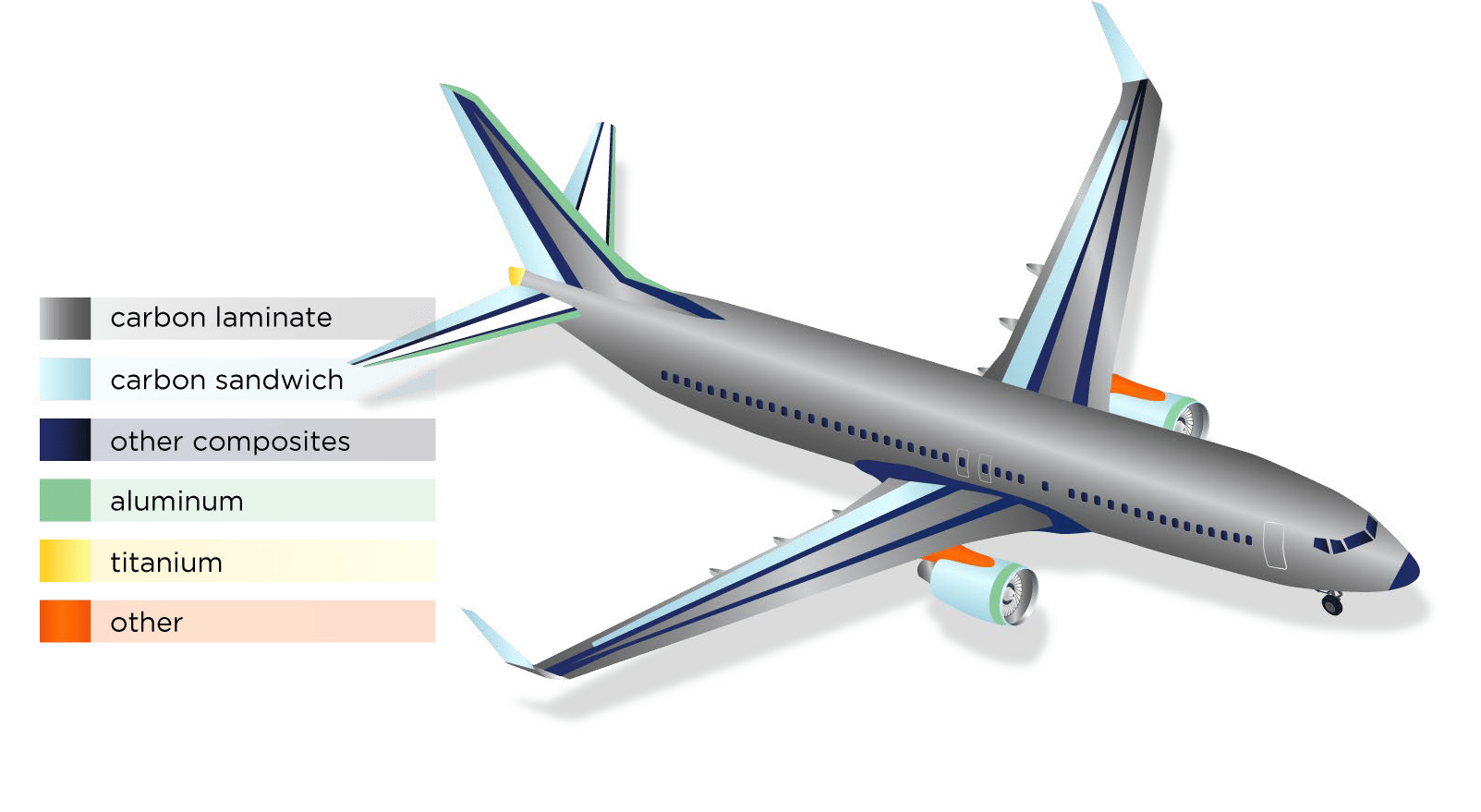

Aircraft are made up of over 50% carbon-fiber composite. While incredibly lightweight and strong, such aircraft composites are not always sufficiently conductive, thus requiring additional protection to mitigate lightning strike damage. This can be resolved by building a metallic mesh into the composite or by using specially designed coatings that are conductive and strong enough to withstand the energy involved in a lightning strike.

Conductive coatings provide protection from aircraft lightning strikes. Anti-static coatings protect electronics from electrical surges. Learn more about providing a safe path for lightning strikes on various materials by watching an informational video here. Learn more about grounding and bonding electrical components/protecting components from static charge build-up by reading this case study.

When you look at an aircraft or spacecraft, be assured that dozens of coatings are applied to keep it safe. From top to bottom, to inside and out, the AS industry coats to keep corrosion and wear from degrading mission-critical assets. It’s the job of coating manufacturers to formulate the highest-performing, longest-lasting, and lightest-weight coatings possible.

Coating Manufacturers Formulate to the Unique Needs of Aerospace Materials and Rigorous Service Conditions

What Types of Coatings Provide the Right Stuff?

Hybrid Crosslinked Coating

Crosslinking known polymers, monomers, and branches can improve coating capabilities, and this process yields several advantages.

- A customized coating via crosslinking combines the performance benefits of two or more polymers and is a good strategy for meeting critical demands. This formulation strategy creates more-durable coating systems that offer lightweight, efficient, and improved protective properties.

- Well-known polymers come with performance testing data that aerospace and coating engineers rely on. Strategic polymer coating formulations are essentially strong and flexible liquid composites that successfully replace heavier materials such as metal additives or rubberized, thicker coatings.

Self-Healing Coatings

A self-healing coating possesses the ability to repair physical damage to the coating and protect the underlying substrate from corrosive media with minimal or very little intervention. The autonomous healing particles could be suspended in a liquid coating system and then cured. With particles embedded in the coating layer(s), it ensures that if the coating layer is disrupted, then the healing agent releases and the CI fills in the scratch from the coating surface at the depths of the scratch.

Self-healing systems can be accomplished by crosslinking a corrosion inhibitor (CI) to other monomer chains or by suspending an enclosed CI-filled microcapsule into the base formula. Both can be efficient ways to formulate, however, the latter could produce a longer, more stable coating shelf life.

Thermal management coatings for space and aircraft provide AS materials extra protection in extreme temperature environments, and protect the underlying coating or substrate from damage. Consider the need for extreme cold and heat on space materials. For instance, space coatings require protection from electrical conductivity, atomic oxygen, UV or solar radiation, and require coatings to prevent damage.

Urethane Coatings

The urethane topcoat is the topline defense between the aircraft’s outer shell and the environment. Every aircraft needs several paint refreshes or new liveries in its service life, which can cost between $150K and $200K per job. A well-made and applied topcoat is critical.1

Electronics and Avionics Coatings

Conformal coatings protect printed circuit boards, wired systems, and electronic components from unfavorable factors such as corrosion, salt-spray, moisture, shock, dust, fungus, and more. These non-conductive coatings on terminals and circuit boards help prevent electronic failure and can extend the service life of protected components. There are many types of electronic conformal coatings such as acrylic, epoxy, silicone, parylenes, polyurethane, and ultra-thins.

Choosing the correct conformal coating for an aerospace component requires research to qualify the part and ensure the coating’s capacity is a match. For instance, some PCB coatings can be difficult to remove, some are longer lasting or more durable than others, and some have a thick appearance, while some are ultra-thin. Color or tinting, ease of application, and other factors may need to be considered.

Another important consideration for conformal coatings is which standards the chosen coating meets, such as IPC-CC-830, or Mil-I-46058C. In order to recycle PCBs, it is ideal that the coating is removable. In this situation, there may not be an abundance of options, but Nyform fills a service gap. It is a durable, long-lasting, thin-film coating that can be safely and efficiently removed without difficult or time-consuming processes.2

Paints and Pigments

The most noticeable coating on an aircraft is the paint, but paints are not only for design or identification purposes. The main reason for painting the aircraft is to prevent material failure and keep the underlying materials safe from corrosive media. The pigments dispersed into a paint base are designed and produced to remain solid in the base coating and impart the bright color that we see. Pigments can be classified as functional or decorative, organic or inorganic, and pigment selection is determined by the required performance for a specific application.

Interior and exterior paints are formulated to the exact conditions they will encounter in service. Paint chemistries are strategically chosen to provide benefit to the underlying coatings and/or the substrate they are applied to. From factoring in substrate surface tension for optimal adhesion or ensuring low observation with covert paint, there are many considerations when it comes to aircraft paint.

Space Coatings

Space materials require coatings that can provide optimal survivability and longevity over critical parts. The environment in space is very different from that of Earth, so coatings chosen for space applications must slow erosion rates, material stresses, and oxidation. The most corrosive elements to space materials are ATOX-Atomic Oxygen; a type of corrosion not found on earth that is considered the most serious and hazardous to spacecraft materials. ATOX exists at altitudes between 200 and 700 km according to the ESA (European Space Agency).3

Coating types that provide benefits that reduce corrosion and wear in space environments are lightweight thin-film coatings that have mission-specific functions, exotic metal coatings, and high-performance pigment coatings designed to provide high-level UV and radiation protection.

TABLE 1 ǀ Coating types, applications, and benefits.

What Do Modern Aerospace Coatings Look Like, and How Are Additive Technologies Helping?

Modern aircraft builds incorporate more composite materials to lighten the overall weight and improve fuel efficiency. The idea is that all materials on the aircraft become lighter and as efficient as possible. High-tech additives, combined with the protective properties of conventional coating systems, offer new and enhanced capabilities and an opportunity to strengthen the coating performance without adding weight. From improving mechanical properties, to preventing the spread of contagious viruses, high-tech, multi-functional coatings are interesting for the aerospace industry. Here are some next-generation coatings that meet today’s challenges head-on with new ways to protect air and space materials.

Multi-Polymer Electronic Conformal Coating with Additives

Conformal coatings are high-performance materials suited to meet the complex demands of aerospace electronics such as PCBs, circuit assemblies, and electronic components. Conformal coating enhancements are achievable by crosslinking polymers and adding nanoparticles to provide customized performance features. There can be service gaps in conformal coatings, for example, pinholes or bubbles, low adhesion, or a coating that is not removable.

A new conformal coating on the market, Nyform, is a crosslinked polymer, ultra-thin conformal coating matrix with tints or fluorescent additives. This coating’s clear or tinted lightweight protection is highly durable, capable of withstanding extreme environments, and is fully and safely removable.

Anti-Counterfeit Covert Coatings

With supply-chain changes, counterfeiting of aerospace parts is increasing at an alarming rate. The problem has been ongoing for decades, and the FAA estimates that counterfeit or unapproved parts contributed to 174 U.S. aircraft crashes and accidents between 1973 and 1996.

They also estimate that 2% of the 26 million aircraft parts installed each year are counterfeit. Even with new OEM and FAA standards for defending AS against counterfeit parts, the problem remains without a solution, and mitigation is largely focused on ensuring counterfeit parts do not become installed on an aircraft. While important, the mitigation in place doesn’t address the overall loss of revenue.

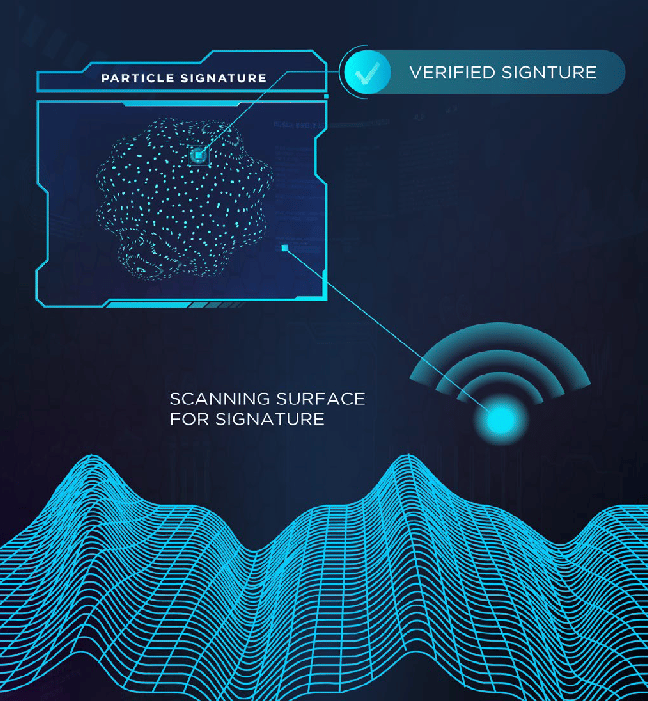

Intelligent new anti-counterfeit coating innovations could help. Machine-readable coatings are good strategies for alleviating counterfeit parts. The suspension of a unique, technologically advanced additive into a high-performance surface coating serves as a covert chemical QR code, providing a scannable signature that follows the part throughout its service life. A new coating, Surface Trace, is a new way to mitigate these concerns. Surface Trace coatings provide a scannable read of the particles embedded in the coating and records this unique signature, safeguarding critical parts. The base coating is already approved by aerospace OEMs, which is shortcutting the product’s long approval process.

Capturing the particle inside of the cured coatings creates a signature that can be recorded and traced to the authenticated item.

Microbial and Viral Surface Contamination Solutions

Airline cleaning and disinfecting costs post-COVID are exceptionally high and unsustainable. Table 2 provides estimates of past, current, and future spending on cleaning chemicals alone. These figures do not consider the cabin-cleaning crew spend.

TABLE 2 ǀ Airline cleaning and disinfecting costs (post-COVID).

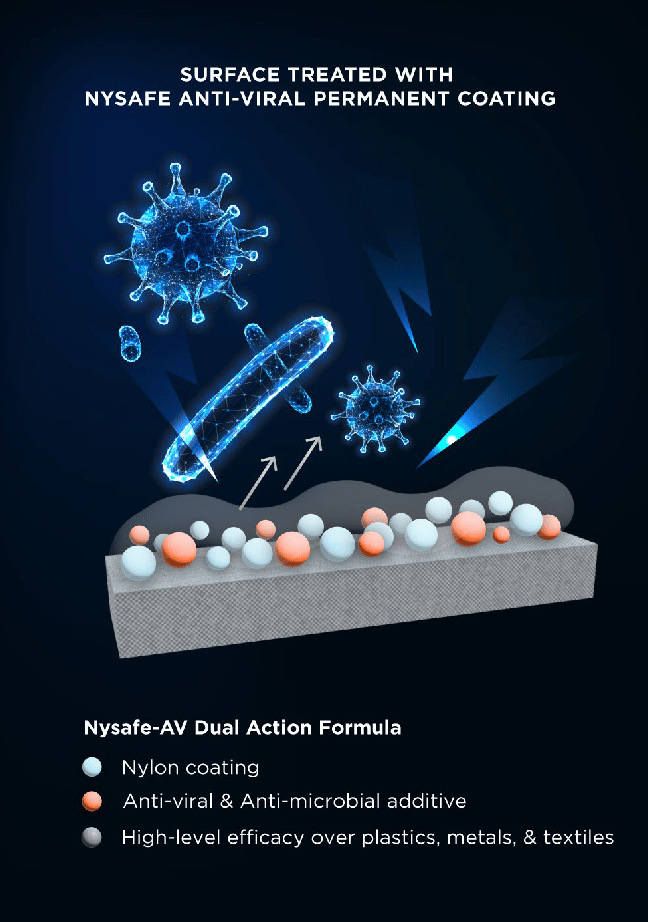

What was missing in the AS industry was a permanent solution to pathogen contamination. Mass transit, medical, and hospitality industries must incorporate new, more permanent technologies to prevent the spread of viruses and bacteria if they want to decrease their costs. During the pandemic there was a mad dash to find a coating that would eliminate contamination and decrease the spread in public spaces. The main problem was finding an easy-to-apply product that could provide durable, long-lasting protection.

Nysafe 700 and 900 anti-virals are long-lasting, durable, high-performance surface coatings formulated from popular, well-known technologies approved by Boeing, Airbus, Embraer, and others used to protect high-value parts from damage. Nysafe contains two elements that collectively and significantly reduce the viral and bacterial contamination load on all high-touch surfaces. The first is a known polymer that microbes cannot penetrate or grow on. The second is an anti-viral additive known for affecting and reducing viral load on surfaces. The product is safe for humans and is a long-term solution proven and tested against viruses and bacteria. As air and space companies innovate and materials evolve, so must coatings. The addition of additives to existing technologies and emerging technologies provides coating manufacturers with a path to innovate for these modern and changing times. In the last 10 years, the push to phase out harmful chemicals like chrome, PFAS, benzene, and others on the chemical watch list is an invitation to create next-generation products that are safer and better for the environment.

A textile surface treated with Nysafe anti-viral permanent coating to prevent microbes from penetrating and growing on potentially costly substrates.

The aerospace community and U.S. government agencies provide a coating innovation path through partnerships and grants available to solve, disrupt, and improve current technologies.

What Challenges Exist When Reformulating or Innovating New Coating Technologies?

Today there is a significant industry drive to innovate next-generation coating products that have the potential to outperform chrome, PFAS, or other obsolete or phased-out harmful chemicals. This is a big task since these coatings effectively prevent corrosion.

Collaborating with aerospace OEMs is crucial to modernize current coating tech and to innovate future coatings. The addition of additives to both existing and emerging technologies provides coating manufacturers with a path to innovate for these modern and changing times.

For more information, click here.

References

1 Hayward, J.; Karuwa, T. (2023, November 3). How much does it cost to paint an aircraft?. Simple Flying. https://simpleflying.com/aircraft-paint-cost/

2 Case study #8: Nygone Surface Coating Remover. Nycote Laboratories. (2023, August 11). https://nycote.com/case_studies/coating-remover/

3 Corrosion in Space. European Space Agency. http://esmat.esa.int/Publications/Published_papers/Corrosion_in_Space.pdf