Ready to proof -- Clare 5/21/21

KJ proofed on 5/21

KP proofed 5-23 - clean for me

Ready to proof -- Clare 6/18/21

KJ proofed on 6/21

Proofed by Karen on 6-21-21

INDUSTRY UPDATES

“Our aerospace sealants, coatings and adhesives helped ULA provide protection for the Atlas V 541 rocket, which aided the Perseverance rover in reaching its final destination,” said Sam Millikin, PPG Global Director, Coatings and Sealants, Aerospace. “We are proud to support this important and historic mission and look forward to a continued partnership with ULA for years to come.”

PPG’s application support center (ASC) in Atlanta, Georgia, worked closely with ULA to supply the products and provide technical support.

SYLMAR, CA – PPG recently announced that it provided aerospace sealants, coatings and adhesives to United Launch Alliance (ULA) for the ATLAS V 541 rocket that launched NASA's Perseverance rover to Mars in July 2020. The rover landed on the Red Planet in February 2021 after its nearly seven-month journey through space.

As one of the most powerful rockets in ULA’s Atlas V fleet, the 541 configuration with four solid rocket boosters provides optimum performance to precisely deliver a range of mission types.

PPG products protecting the rocket include PPG DESOTHANE™ CA8200 Series HS polyurethane topcoat; PPG PR-2001 Class B rapid-curing fuel tank sealant, which is a two-part, epoxy-cured PERMAPOL™ P-3.1 polythioether compound; and PPG PR-1665, which is a cryogenic potting and molding compound with high tear and tensile strength.

PPG Products Protect Rocket That Launched NASA’s Perseverance Rover to Mars

Photo courtesy of United Launch Alliance.

Scientists Use Neural Networks to Rethink Material Design

HOUSTON – The microscopic structures and properties of materials are intimately linked, and customizing them is a challenge. Rice University engineers are determined to simplify the process through machine learning. To that end, the Rice lab of materials scientist Ming Tang, in collaboration with physicist Fei Zhou at Lawrence Livermore National Laboratory, introduced a technique to predict the evolution of microstructures in materials — structural features between 10 nanometers and 100 microns.

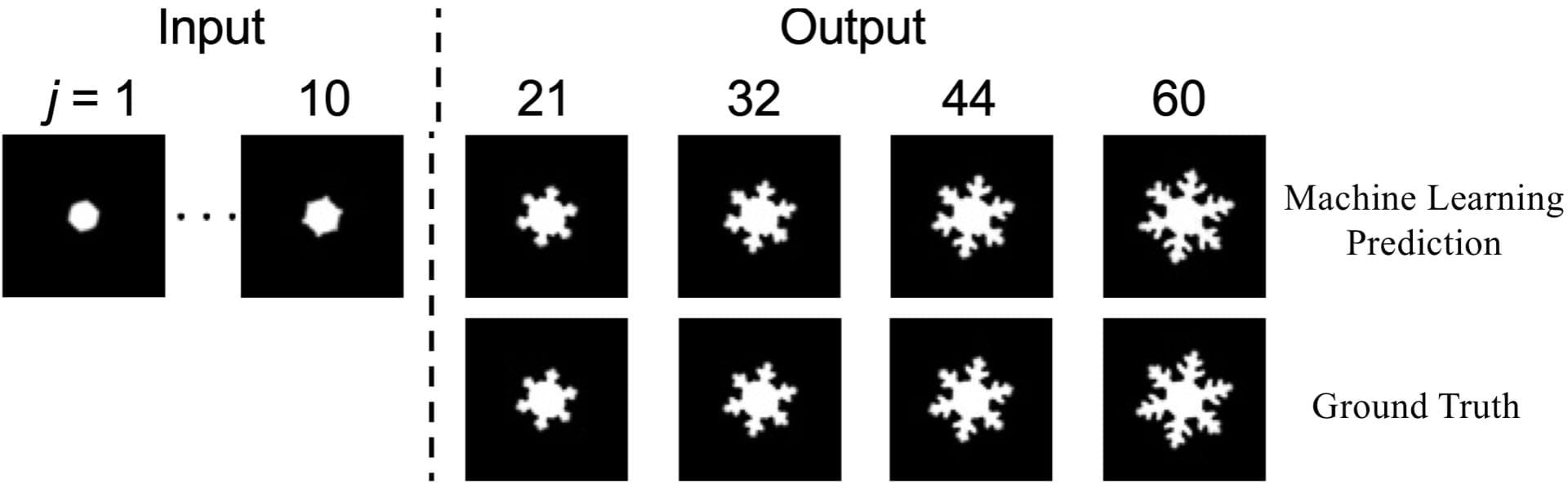

Their open-access paper in the Cell Press journal Patterns shows how neural networks (computer models that mimic the brain’s neurons) can train themselves to predict how a structure will grow under a certain environment, much like a snowflake forms from moisture in nature. In fact, snowflake-like, dendritic crystal structures were one of the examples the lab used in its proof-of-concept study.

“In modern material science, it’s widely accepted that the microstructure often plays a critical role in controlling a material’s properties,” Tang said. “You not only want to control how the atoms are arranged on lattices, but also what the microstructure looks like, to give you good performance and even new functionality.

“The holy grail of designing materials is to be able to predict how a microstructure will change under given conditions, whether we heat it up or apply stress or some other type of stimulation,” he said.

Tang has worked to refine microstructure prediction for his entire career, but said the traditional equation-based approach faces significant challenges to allow scientists to keep up with the demand for new materials. “The tremendous progress in machine learning encouraged Fei at Lawrence Livermore and us to see if we could apply it to materials,” he said.

Fortunately, there was plenty of data from the traditional method to help train the team’s neural networks, which view the early evolution of microstructures to predict the next step, and the next one, and so on.

“This is what machinery is good at, seeing the correlation in a very complex way that the human mind is not able to,” Tang said. “We take advantage of that.”

The researchers tested their neural networks on four distinct types of microstructure: plane-wave propagation, grain growth, spinodal decomposition and dendritic crystal growth. In each test, the networks were fed between 1,000 and 2,000 sets of 20 successive images illustrating a material’s microstructure evolution as predicted by the equations. After learning the evolution rules from these data, the network was then given from 1 to 10 images to predict the next 50 to 200 frames, and usually did so in seconds.

The new technique’s advantages quickly became clear: The neural networks, powered by graphic processors, sped the computations up to 718 times for grain growth, compared to the previous algorithm. When run on a standard central processor, they were still up to 87 times faster than the old method. The prediction of other types of microstructure evolution showed similar, though not as dramatic, speed increases.

Comparisons with images from the traditional simulation method proved the predictions were largely on the mark, Tang said. “Based on that, we see how we can update the parameters to make the prediction more and more accurate,” he said. “Then we can use these predictions to help design materials we have not seen before.

“Another benefit is that it’s able to make predictions even when we do not know everything about the material properties in a system,” Tang said. “We couldn’t do that with the equation-based method, which needs to know all the parameter values in the equations to perform simulations.”

Tang said the computation efficiency of neural networks could accelerate the development of novel materials. He expects that will be helpful in his lab’s ongoing design of more efficient batteries. “We’re thinking about novel three-dimensional structures that will help charge and discharge batteries much faster than what we have now,” Tang said. “This is an optimization problem that is perfect for our new approach.”

Rice graduate student Kaiqi Yang is lead author of the paper. Co-authors are Rice alumnus Yifan Cao and graduate students Youtian Zhang and Shaoxun Fan; and researchers Daniel Aberg and Babak Sadigh of Lawrence Livermore. Zhou is a physicist at Lawrence Livermore. Tang is an Assistant Professor of Materials Science and Nanoengineering at Rice.

The Department of Energy, the National Science Foundation and the American Chemical Society Petroleum Research Fund supported the research.

Engineers at Rice University and Lawrence Livermore National Laboratory are using neural networks to accelerate the prediction of how microstructures of materials evolve. This example predicts snowflake-like dendritic crystal growth. Photo courtesy of the Mesoscale Materials Science Group.

Philippine Lead Paint Regulation Shortlisted for 2021 Future Policy Award

QUEZON CITY, Philippines – Government, industry and civil society groups in the Philippines applauded the shortlisting of the country’s landmark lead paint regulation for the Future Policy Award 2021 (FPA 2021) by the World Future Council (WFC), Hamburg, Germany. The 12 shortlisted policies from a total of 55 nominated policies from 36 countries were announced the end of May. The Lead in Paint Control Regulation No. 429 (2018) in Ethiopia was also shortlisted for the award.

FPA is the first and only award that celebrates policies for the benefit of present and future generations on an international level. This year’s FPA puts a spotlight on the most effective policy solutions that minimize the adverse effects of exposure to chemicals on human health and the environment.

Among the shortlisted policies is the Philippines’ Department of Environment and Natural Resources (DENR) Administrative Order 2013-24, also known as the Chemical Control Order for Lead and Lead Compounds (CCO), which bans the use of lead in the production of paints and other processes, including the manufacture of toys, school supplies, cosmetics and food-contact packaging materials. The CCO imposes a total maximum lead content of 90 parts per million (ppm) for all paints and sets a phase-out period for lead-containing architectural, household and decorative paints (2013-2016) and lead-containing industrial paints (2013-2019).

The WFC summarized the policy, “With the CCO, the Philippines became the first Southeast Asian country to successfully implement legislation towards lead-safe paint. The policy’s objective is to increase awareness of the toxicity of lead exposure and to provide safer alternatives to protect the health of the population and the environment. It comprises a roadmap with clear definitions, phase-out plans, and decisive instruments with special attention to children. The CCO combines a collaborative top-down and bottom-up strategy with successful implementation. While globally only a few countries have enacted comprehensive bans on the use of lead additives in all paints, the Philippines demonstrate that it is entirely possible to restrict the use of lead in all paints to the maximum limit of 90 ppm, including in industrial paints, which generally have lead concentrations that are up to 10 times higher. By 2020, the local industry had beaten the phase-out deadline for lead paints with a total of 1,395 paint products certified through the new Lead Safe Paint® Certification programme.”

“We consider the CCO’s shortlisting for the FPA 2021 as a high point in the industry-wide transition to lead-safe paint production made possible by the promulgation of a mandatory policy that was developed with the participation of paint manufacturers, raw materials suppliers, environmental health activists and government regulators. Local paint makers have now switched to non-leaded ingredients for pigments, driers and rust inhibitors, indicating the doability and viability of making the shift,” said Derrick Tan, President, Philippine Association of Paint Manufacturers (PAPM).

“The shortlisting of the CCO for FPA 2021 is a testament to our country’s resolve to protect children’s health from preventable sources of lead poisoning such as lead in paint, dust and soil, which can seriously affect a child’s growth and development, including causing intellectual impairments and behavioral issues,” said Manny Calonzo, Adviser for the Lead Paint Elimination Campaign of the EcoWaste Coalition and the International Pollutants Elimination Network (IPEN). “This shared achievement should inspire all sectors to sustain the monitoring of compliance to the CCO and related regulations, and to the adoption of further measures that will, for example, address ‘legacy paint’ or lead paint applied in the past, especially in homes, schools, playgrounds and other places frequented by children.”

“The shortlisting of the lead paint regulations of the Philippines and Ethiopia, which were both developed with the essential input and participation of various sectors, including environmental health NGOs, highlights the need for countries to enact and enforce strong laws banning lead in all paints to safeguard children's health,” said Sara Brosche, Science Advisor and Manager of IPEN Global Lead Paint Elimination Campaign. “IPEN is privileged to have collaborated with the EcoWaste Coalition and Pesticide Action Nexus-Ethiopia in building support for the adoption of exemplary lead paints laws in their respective countries."

Nominated policies to the FPA are judged based on the 7 Principles of Future-Just Lawmaking, which are derived from the seven principles for sustainable development law adopted by 192 states at the 2002 Johannesburg World Summit on Sustainable Development. Among the members of the jury for the FPA 2021 is Dr. Marcos Orellana, UN Special Rapporteur on Toxics and Human Rights, who said, “Effective and innovative laws and policies for the sound management of chemicals and wastes are indispensable to secure a toxic-free environment for all.”

The FPA is awarded by the WFC and is organized this year in partnership with the United Nations Environment Programme (UNEP), Strategic Approach to International Chemicals Management (SAICM), International Labour Organisation (ILO), Organisation for Economic Co-operation and Development (OECD), United Nations Institute for Training and Research (UNITAR), and the United Nations Development Programme (UNDP).

Juan Miguel Cuna, DENR Undersecretary for Field Operations and Environment, who was then the Director of the Environmental Management Bureau when the CCO was being deliberated, commented, “We are deeply honored to have been nominated and subsequently shortlisted for the FPA 2021 as the global award recognizes a groundbreaking policy that our government had promulgated with vigorous support from our paint industry and civil society partners to protect vulnerable populations, particularly children, women and workers, from the harmful effects of lead exposure.”

Photo courtesy of the EcoWaste Coalition.

RadTech 2022 Call for Papers Is Open

CHEVY CHASE, MD – RadTech International North America is accepting abstracts for the 2022 RadTech UV+EB Technology Conference & Exposition, scheduled for May 10-12, 2022, at the Hyatt Regency Orlando in Orlando, Florida. This will be an in-person conference, and organizers will follow the latest guidance on health and safety practices.

RadTech is looking for high-quality technical papers that discuss advances in LED technology, additive manufacturing/3D printing, electron beam, coatings, materials, adhesives, inks, formulation, chemistry, equipment, testing, and more.

Technical papers should be no longer than 25 minutes in length, with five minutes for Q&A. The online Abstract Submission Form should be completed prior to Sept. 24, 2021. Descriptions should be sufficiently comprehensive to allow assessment of the scope and content of papers by the Conference Committee. The committee will select papers, and speakers will be notified whether or not they have been selected by November 2021.

Photo courtesy of RadTech.

Research Firm Reports Decline in Industrial Coatings Market in 2019 and 2020

DUBLIN – A new study from Research and Markets finds that the industrial coatings market saw a decline of about 3% between 2019 and 2020. The research firm expects the industrial coatings market to now to be on the track to recovery, provided the second wave of the COVID-19 pandemic is brought under control as soon as possible.

The report analyzes the industrial coatings market for coating type, technology and application by major geographic regions, and provides an outlook for future technologies. With 47 major companies profiled in the report, key business trends focusing on product innovation and development, mergers and acquisitions, joint ventures, and other recent industry developments are discussed.

Visit Research and Markets’ website for more information about the report, titled Industrial Coatings — A Global Market Overview.

According to the report, Europe, North America and South America are the regions that have suffered the brunt of decreases in demand for industrial coatings, and the recovery in these regions is likely to be slower over the coming years. Asia-Pacific has been the outlier in this regard, as the region experienced the lowest decrease between 2019 and 2020, primarily because China maintained positive growth during that time frame, although growth in 2019 and 2020 was less than in previous years.

In terms of product type, the report finds that solvent-based industrial coatings experienced the highest worldwide demand during 2019 and 2020, accounting for a 43% share in 2020. The company expects that the global market for water-based industrial coatings will see the fastest growth from 2020 to 2026, with a projected compound annual growth rate of 3.8%.

Irina Vodneva/iStock/Getty Images Plus, via Getty Images