Ready to proof -- Clare 6/8/22

KJ proofed on 6/14

Ready for author

FORMULATING WITH MIKE

How Pigments Affect Coating Properties

By Mike Praw, Senior Applications Scientist – Paints, Coatings and Inks, Indorama Ventures: Integrated Oxides and Derivatives, The Woodlands, TX

My June column discussed how light and pigment interactions affect hiding, tint strength and other coating properties. This article will continue on the subject of pigments.

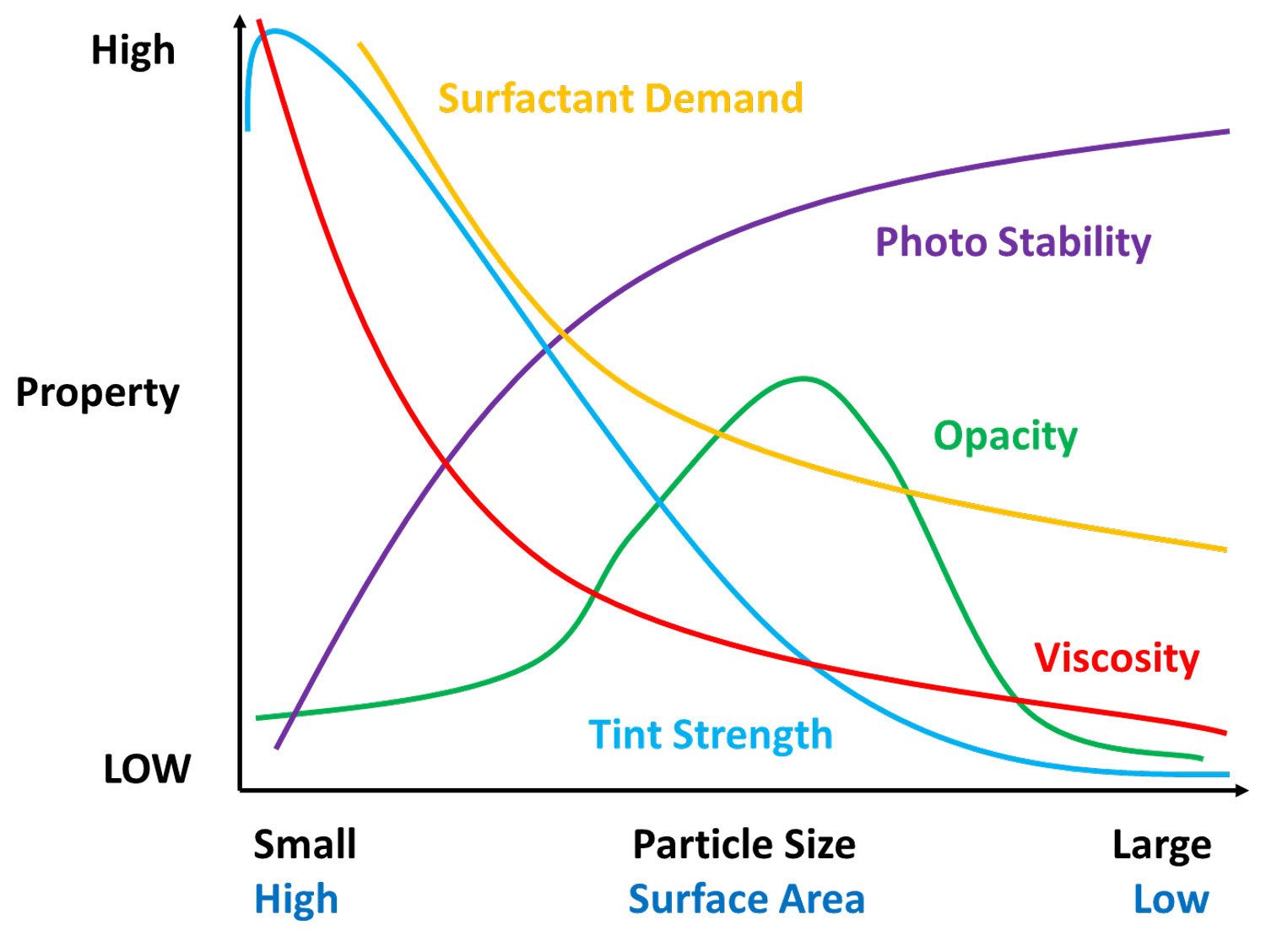

Each pigment manufacturer optimizes particle size for the specific properties for that pigment grade. Hiding, tint strength, photo stability, viscosity and surfactant/resin demand are all affected differently by particle size (Figure 1). So, it is important to maintain the original particle size. We do not want to reduce the actual primary particle size during dispersion, but break up agglomerates and aggregates to return to the primary particle size.

FIGURE 1 ǀ Particle size versus properties.

Color or tint strength is how well a pigment maintains its color when mixed with other pigments. For example, mixing a low-tint-strength black with white would yield a light gray color, but the same amount of high-strength black would result in a much darker gray. Notice how in Figure 1, tint strength and opacity need different particle sizes for maximum effect. Therefore, pigment manufacturers have different grades/particle size distributions of the same pigment.

Primary pigments are divided into three classes: organic, inorganic and carbon black. Table 1 summarizes some of the properties between these. Examples of primary pigment colors can be found in Figure 2.

TABLE 1 ǀ Primary pigment properties.

FIGURE 2 ǀ Examples of primary pigments.

Extender pigments are added to a coating to lower gloss, improve hiding, affect pH, affect rheology or settling, and generally improve or diminish properties such as hardness, abrasion resistance, water penetration, chemical resistance, etc. They are usually lower in cost than primary pigments and can be used at higher levels in coatings. Their refractive index is close to the resins’ refractive index (~1.4 — 1.6) so they can be used in limited concentrations to formulate clear coatings. Extender pigments are often added to a coating to lower cost by “filling” the coating. Common extender pigments and their properties are shown in Table 2.

TABLE 2 ǀ Extender pigment properties.

In the next part of this pigment series, which will appear in the August issue, I will cover some of the terms and calculations used for pigments.

All information contained herein is provided "as is" without any warranties, express or implied, and under no circumstances shall the author or Indorama be liable for any damages of any nature whatsoever resulting from the use or reliance upon such information. Nothing contained in this publication should be construed as a license under any intellectual property right of any entity, or as a suggestion, recommendation, or authorization to take any action that would infringe any patent. The term "Indorama" is used herein for convenience only, and refers to Indorama Ventures Oxides LLC, its direct and indirect affiliates, and their employees, officers, and directors.