Ready to proof -- Clare 5/17/21

LInk sent to author on 5/18

Clean

DID YOU KNOW?

There is Significant Interfacial Polymer in Structured Latex Particles

Video credit: ilyast / Creatas Video, via Getty Images

Did you know that there is a significant to a great deal of interfacial (i.e. mixed) polymer in structured latex particles, even core-shell varieties? This occurs by the very nature in which these composite particles are created — a second-stage monomer is polymerized in the presence of a previously formed, first-stage polymer.

So is this interfacial material both necessary and good? The answer to both questions is yes! In fact, the creation of this interfacial polymer “phase” ties together the first- and second-stage polymers, much like the polymer entanglements that are created between adjacent particles during the latter stages of latex film formation. It is what you “buy” when you produce such composite latex particles, i.e. the bonding of the two polymers together for their final application properties. This is why eventual film properties of composite core-shell (or other morphologies) latexes are usually superior to those achieved by physically blending two separate latexes. It is also necessary because the interfacial polymer comes about during the phase separation process during second-stage polymerization within the composite latex particle.

Polymer physicists have studied the interfacial zone between two dissimilar polymers and have long ago showed how the “thermodynamic equilibrium width” of this zone is inversely related to the interfacial tension between the polymers. The more dissimilar the polymers, the higher their interfacial tension and the narrower the interfacial zone. For a typical, commercially important polymer pair, the width of this zone is perhaps 10 nm. Conversely, for only somewhat dissimilar polymers, the width of this zone can be significantly more substantial. And this width is not dependent upon latex particle size.

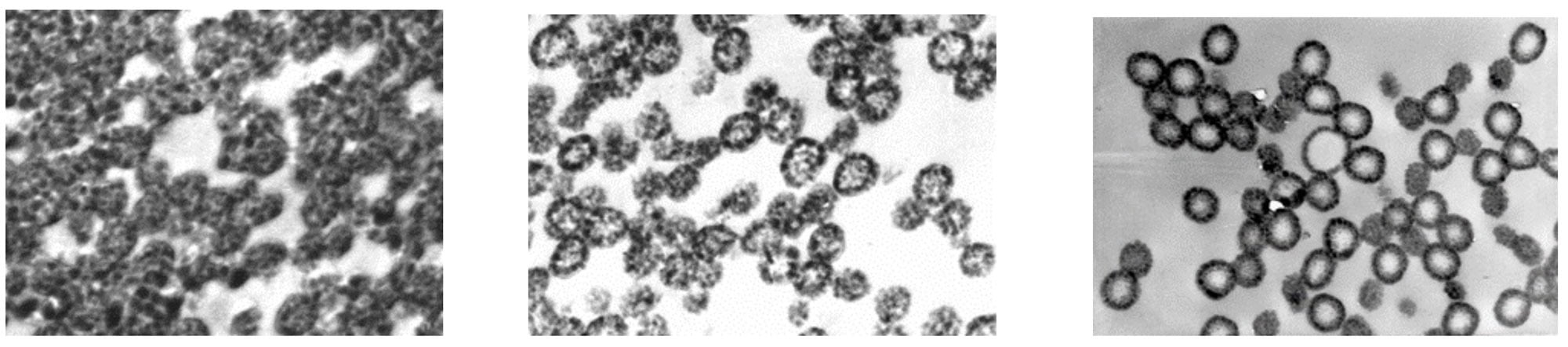

This means that in very small composite particles (say 80 nm), the portion of the particle volume occupied by mixed polymer might be as high as 50% (recall the strictures of spherical geometry). The larger the overall particle, the less this portion. By extension, one can appreciate that the overall ratio of the two polymers in the composite particle can lead to conditions in which the majority of one polymer resides in the interfacial zone, while a significantly smaller portion of the other resides there. Below we present several transmission electron microscope images in which the portion of interfacial polymer ranges from very high (on the left) to minimal (perhaps ~ 10%) for the well phase separated particles on the far right.

This intriguing subject is treated in detail in our STEP 2 and 3 workshops that are described on our website, www.epced.com. We invite your comments and questions by contacting us at info@epced.com.

The “Did You Know….?” series is a bi-monthly note from Emulsion Polymers Consulting and Education (EPCEd) that is intended to present simple questions about topics that are important to those working in the emulsion polymers area. Short and concise answers to those questions are presented to educate readers and to elicit comments and further discussion. Some readers will already know the answers and be familiar with the topic while others, especially those newer to the field, will benefit from the answers and discussion. Experienced practitioners may also find new insights in the discussion. Paint & Coatings Industry magazine has partnered with EPCEd to share the “Did You Know” notes with our readers throughout the year.