Ready to proof -- Clare 5/12/23

KJ proofed on 5/12

DID YOU KNOW?

What Does “Starve-Fed” Really Mean?

Video credit: ilyast / Creatas V1ideo, via Getty Images

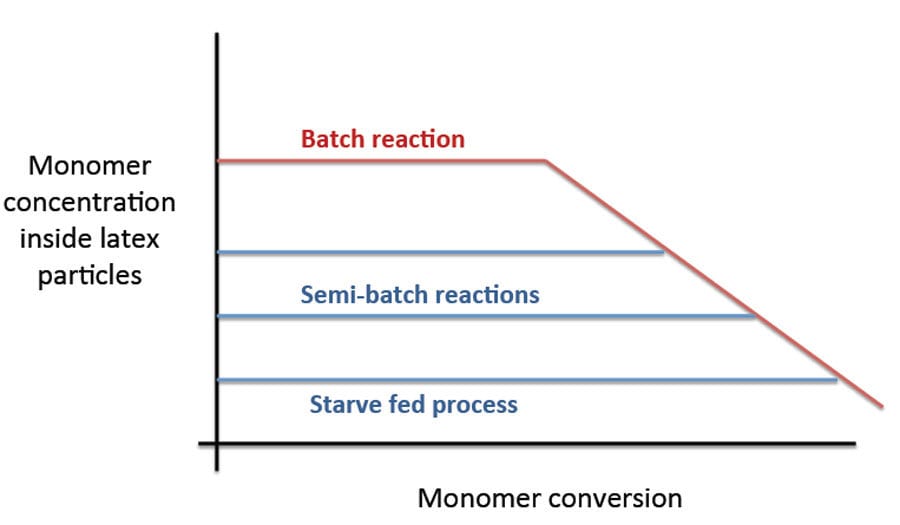

Semibatch emulsion polymerizations are predominately run in “starve-fed” mode, but what does that really mean? It is generally understood to mean that the monomer concentration in the particles is maintained at a level well below its maximum (saturation) value, which is ~5-7 M, depending on the monomers. Typically monomer concentration in the particles is kept at ~0.5-1 M by varying the monomer feed rate, but this can vary significantly depending on the specific process. There are two main reasons for running in “starve-fed” mode, and your selection of how starved you want to run your process depends on the relative value you attach to each objective:

- Maintaining low monomer concentration in the particles decreases the overall polymerization rate so that the reaction temperature can be controlled.

- Much better control of the copolymer composition distribution can be obtained because composition drift can be largely eliminated (more starved gives better control).

However, other factors are also important and should be considered. The overall reaction rate is roughly proportional to the number of particles, so for a given heat-removal capacity in your reactor, smaller size particles (higher particle number) require lower monomer concentration in the particles. This means that a change in particle size likely requires a change in monomer feed rate.

But, it is not that straightforward. Reducing monomer concentration also decreases molecular weight. Possibly even more significant if acrylates are involved, is that lower monomer concentration may result in more branching and crosslinking, which could impact multiple properties including film formation. Temperature is also an important factor; higher reaction temperatures give a larger temperature difference between the jacket and reactor, thereby allowing reactions to be run faster (thus you can use higher monomer concentration in the particles). Finally, comonomer composition must be considered. If there are large differences in the water solubility of the monomers, a more starved system will reduce the impact of having appreciable amounts of hydrophilic monomers (e.g. functional acids, hydroxy functional monomers) in the aqueous phase and not in the particles.

As always, we welcome your comments and questions by contacting us via our website, www.epced.com.

The “Did You Know….?” series is a bi-monthly note from Emulsion Polymers Consulting and Education (EPCEd) that is intended to present simple questions about topics that are important to those working in the emulsion polymers area. Short and concise answers to those questions are presented to educate readers and to elicit comments and further discussion. Some readers will already know the answers and be familiar with the topic, while others, especially those newer to the field, will benefit from the answers and discussion. Experienced practitioners may also find new insights in the discussion. Paint & Coatings Industry magazine has partnered with EPCEd to share the “Did You Know” notes with our readers throughout the year.