COATINGS SUPPLier HANDBOOK

Advertorial

ADDITIVES

Siltech Corporation:

Your Technology — Our Chemistry

As an innovation company, Siltech has built our business and reputation by creating new silicones for customers with new applications.

Using our proprietary technologies, Siltech develops, manufactures and markets a full line of organo-functional specialty silicone materials for specific customer applications. Siltech’s track record of innovation and outside-of-the-box problem solving is demonstrated by our broad portfolio of product types. Our early history as an organic surfactant company gives us a different perspective from other silicone manufacturers, and results in classic organic surfactant derivations to silicone such as Silamine®, Silphos® and Silquat® grades. With more than 35 years of experience, and three manufacturing facilities, we offer the coatings industry a broad line of Siltech additives and Silmer® reactive silicones as well as more unique chemistries.

In addition to our extensive portfolio, Siltech welcomes the opportunity to partner with customers to develop unique silicones for specific applications.

Coatings Additives and Silmer® Reactive Silicones

Siltech inks and coatings additives have long been recognized as providing special properties including improved slip, gloss, mar resistance, flow, leveling and foam control. Furthermore, because these silicones are efficient at very low use levels, they are cost effective, and widely used.

Our expertise in and portfolio of reactive silicones aligns with industry needs to bind into a coating as well as to modify resins to obtain hybrid mechanical properties. We have shown in many publications that Silmer reactive silicones can be reacted into films or resins to alter the properties of the final film. These materials increase flexibility, impact resistance, lower slip and COF, as well as provide improved stain resistance. Please check our website for these references and updates.

R&D

Our R&D, technical service, analytical and process R&D laboratories are modern, well-equipped, co-located with our manufacturing facilities and staffed with first-class chemists and engineers.

Recently from our R&D labs, we have created a family of highly cross-linked silicon-based MTQ resins that provide unique properties. These include Silmer VQ resins for addition-cured silicone systems, which provide hardness, strength and toughness while maintaining clarity. Another application of this work is our new mercapto functional silicon products. These highly functionalized resins cross-link with vinyl silicones under UV-cured conditions including UV-cured 3D printers providing up to 300% elongation from a UV-cured system.

We have demonstrated the use of silicone additives to replace PFAS compounds in slip, surface tension reduction, stain resistance, COF reduction and water repellency applications.

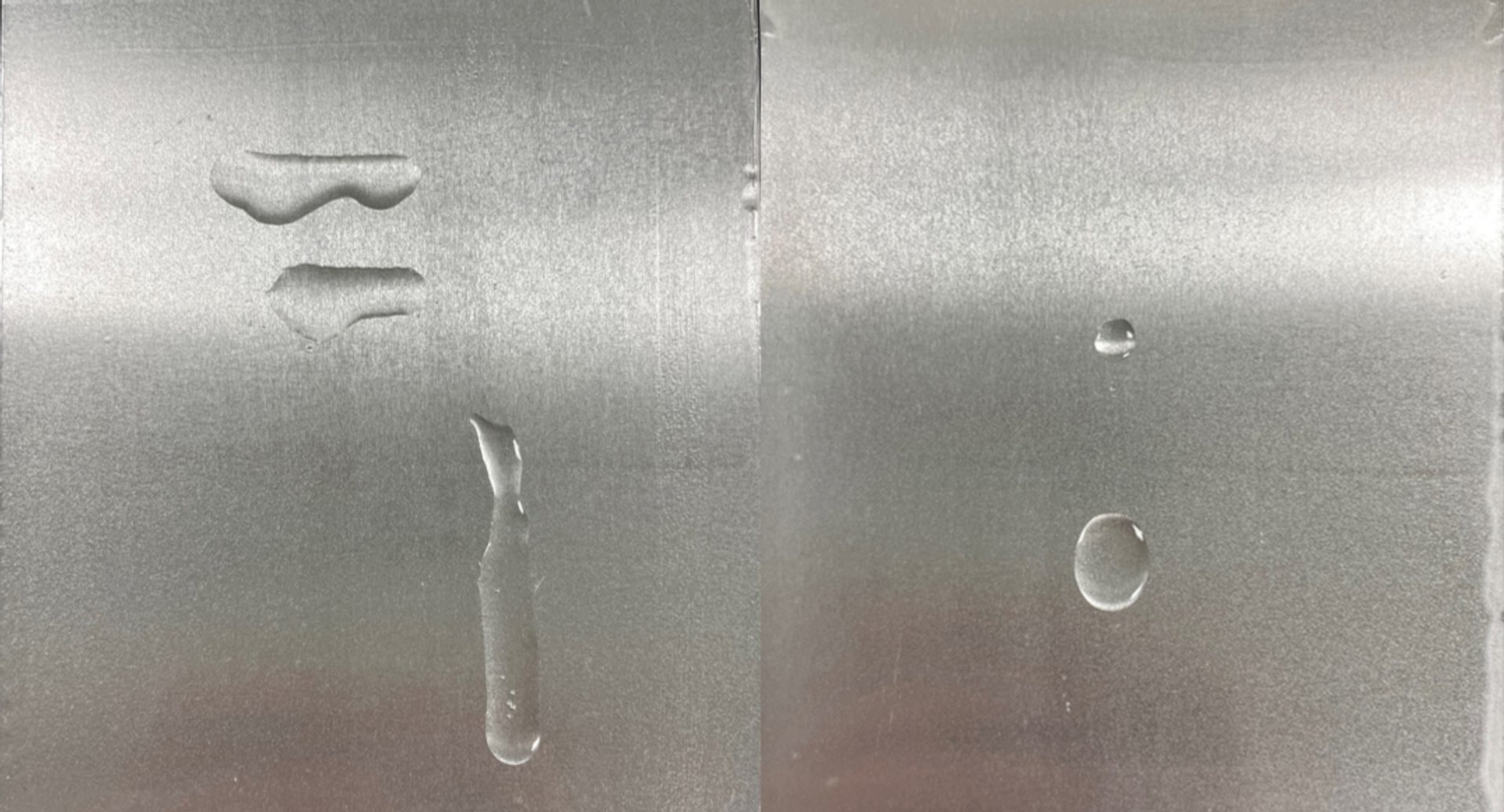

Most recently we have shown oleophobicity, relevant to PFAS replacement, in a UV-cured system with Silmer ACR DT-10.

Our work continues exploring oleophobicity from unique self-assembling organosilicon species with published results expected in 2025.

LEFT–ǀ–WMO droplets on UV-cured coating, no additive. RIGHT–ǀ–WMO droplets on UV-cured coating with 1% Silmer ACR DT-10.

Environmental Standards

ISO 9001:2008 and ISO:14001 registered, Siltech is lessening our impact on the environment with ECOVADIS metrics, plant actions, product offerings which use bio-sourced carbon in our Silsurf® and Silwax® product lines, alternatives to regulatory targeted chemicals, carbon footprint calculations and internal targets and discussion.

Text