COMPANY NEWS

Minwax Picks Vintage Blue as First-Ever Color of the Year

CLEVELAND – Minwax® recently announced its first-ever 2021 Color of the Year: Vintage Blue, a comforting organic color with a balance of green and renewing blue. Vintage Blue is the very first Color of the Year from Minwax, inspiring do-it-yourselfers to think of limitless color stain options when planning their next project.

“Capturing the stain color that reflects our evolving style at home is rooted in our desire to set a calmness and resilience as we move through the uncertainty,” said Sue Kim, Minwax Color Marketing Manager. “Minwax now offers more color choices to express your personal style and bring out the beauty of wood.”

Kim describes Vintage Blue as an organic color that balances nurturing green and renewing blue with subtle gray undertones. The hue creates a nostalgic mood and soothes with its natural strength, elevating everyday objects to new luxury.

Vintage Blue is one of 240-plus color options available in Minwax Wood Finish Water-Based Color Stains, a line of water-based, semi-transparent and new-to-the-world solid stains, offering, according to Minwax, the largest color assortment on the market.

The 2021 Color of the Year is complemented by a coordinating palette of Minwax color stains that includes White Frost, Amber, Carbonite, Denim Blue, as well as Classic Gray, to help consumers make projects their own with more color combinations. Whether adding character to a cherished object or refurbishing an antique find, consumers can use Vintage Blue interior stain in place of paint to bring out wood's inherent beauty while maintaining its texture.

Photo courtesy of Minwax.

Clariant Announces New Pigments Lab in South Africa

MUTTENZ, Switzerland – Clariant Pigments recently expanded its new pigments laboratory in Krugersdorp, near Johannesburg, South Africa, which will be a showcase for sustainable color technology. To be officially opened and inaugurated in early 2021, the new facility will serve the emerging Middle East and Africa paints and coatings market.

Marking a commitment to its business in South Africa, Clariant’s investment in the laboratory, which has taken more than 12 months to complete, will increase local color support services to the coatings industry across Africa, Turkey and the Middle East. The new facility also offers increased local employment opportunities and in-house skills development training in color technologies.

“Previously, we were only able to supply pigments as raw materials, but we are proud to now be offering a full spectrum of value-added services including customized color solutions, color matching services or the development of own color recipes to create an unlimited number of shades, for example tinting systems. To complete our services we also offer technical marketing and after sales support,” said Rossitza Dimitrova, Clariant Business Unit Pigments Head of Technical Marketing, Middle East and Africa.

All product offerings, for both decorative and industrial markets as well as solutions for wood coatings, will include pigments and pigment preparations that are lead free, contain low VOC and are free of APEO.

“In South Africa there is a growing demand for both locally produced and sustainable colorants and at Clariant Pigments we can now better serve the local and regional coatings industry with innovative and sustainable ranges of colorant solutions,” said Piers Kure, Clariant Business Unit Pigments Head of Sales, Sub Sahara, Africa.

Clariant’s newly equipped laboratory in Krugersdorp, South Africa. (Photo courtesy of Clariant.)

AkzoNobel Opens R&D Facility for Low-Cure Powder Coatings

COMO, Italy – AkzoNobel has opened a new research center at its site in Como, Italy, that will develop products for the growing area of powder on wood. The new R&D facility, which features an application lab, process lab, and an analytical and testing lab, is dedicated to delivering low-cure powder coatings for use on heat-sensitive substrates such as MDF, plywood, thermoplastics and composites.

The center’s inauguration follows AkzoNobel’s recent acquisition of Stahl’s powder coatings activities, which gave AkzoNobel access to a range of solutions, including unique UV technology. The Como center will now focus on developing an expanding portfolio of low-cure solutions, including low-bake, UV and ultra-low-bake powder technologies. This will enable customers to use less energy during production, gain process speed, and boost their own sustainability profile.

“We’re excited to build on our global leadership position and enter new markets while bringing more surfaces to life for our customers,” said Daniela Vlad, Director of AkzoNobel’s Powder Coatings business. “In addition to strengthening our position as a technology leader, the new facility will also help to accelerate our speed to market so we can reach our customers even faster.”

Vlad added that this is only the first phase of the company’s expansion into powder on wood, with plans in place to open additional R&D centers in Asia and North America. With customers worldwide looking to embrace the sustainability benefits that powder has to offer, powder on wood has become a fast-growing area within the coatings industry.

“The dedicated know-how we have in the new R&D center will enable us to develop a broad range of innovative new surface solutions, particularly for our wood coatings customers,” said Vlad. “Having recently expanded our Como site, it means we can now accommodate a European manufacturing facility for powder on wood and the new R&D center at the same location, which will speed up the service capability we offer to customers in this segment.”

The new R&D facility features an application lab, process lab, and analytical and testing lab, and is dedicated to delivering low-cure powder coatings for use on heat-sensitive substrates. (Photo courtesy of AkzoNobel.)

Greenkote Expands Capacity in Response to Increase in Anti-Corrosion Coating Orders

BROOK PARK, OH – Greenkote, global provider of advanced anti-corrosion metal coatings, recently announced a major expansion of production capacity at its headquarters facility in Brook Park, Ohio. The expansion comes in response to an upsurge in demand for corrosion protection on environmentally exposed metal fasteners and hardware in a number of different industries.

“I don’t know if climate change may be a part of it, but we’re seeing notable increases in anti-corrosion coating orders for all kinds of different metal parts that are exposed to the elements,” said Greenkote CEO Mark Gore. “The orders are coming from a range of sectors, including automotive, rail, electric power distribution, wind power generation, and others. These are all applications that have fasteners, fixtures and other metal hardware exposed to long-term outdoor atmospheric corrosion.”

Gore stated that installation of the additional Greenkote coating equipment in Brook Park has been completed and the facility is now fully operational with significantly expanded capacity. Greenkote provides anticorrosion coating services for construction, automotive, rail, utilities and many other industries in which parts are exposed to weather or harsh and corrosive environments. The company reports that proprietary Greenkote coatings have been replacing several older anticorrosion processes such as galvanizing, hot-dip, sherardizing and metal flake.

Greenkote provides anti-corrosion coating services for industries in which parts are exposed to weather or harsh and corrosive environments. (Photo courtesy of Greenkote.)

PPG Launches Styling Program for Automotive Color Modeling

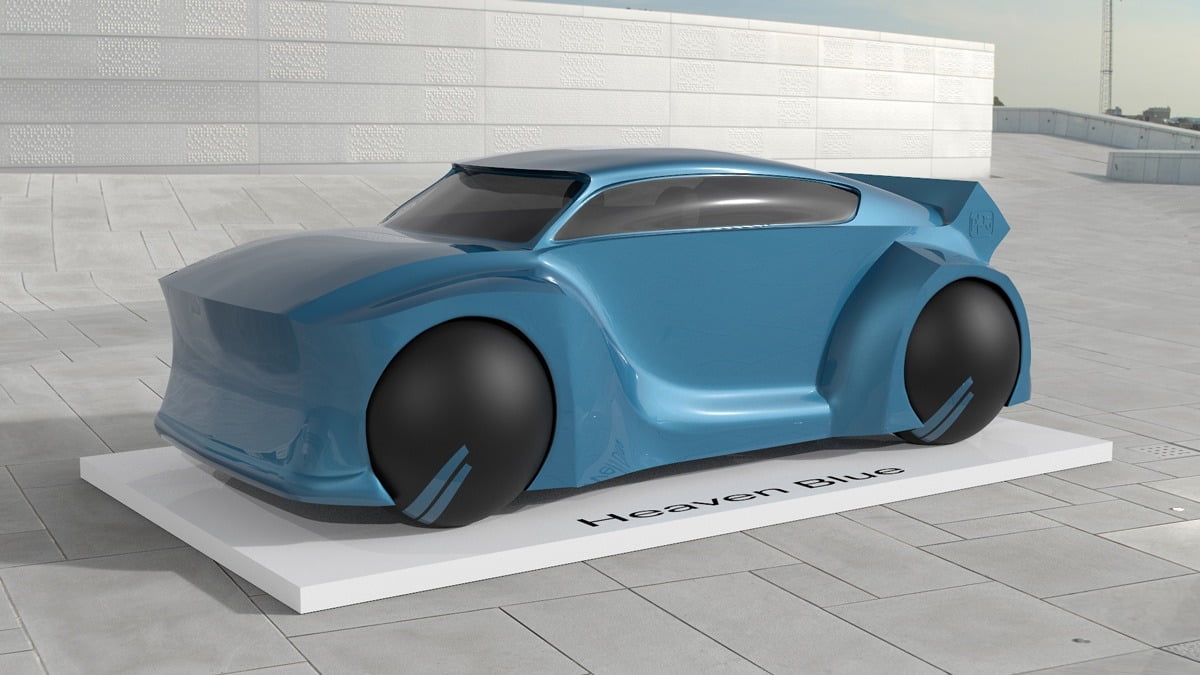

PITTSBURGH – PPG has introduced a digital styling program that enables automotive designers to execute exceptionally realistic three-dimensional modeling of automotive colors and effects on virtual car designs and surfaces. Exclusive to the program is the PPG proprietary “speed shape” that incorporates all the complex shapes, edges, curves and flat surfaces that would comprise any type of automobile. Developed by PPG, the digital vehicle model is designed to depict the interaction of color, geometry and light to create authentic renderings of a vehicle’s surfaces, including its wheels and interior components.

In addition to speed shape, the digital styling program will offer automotive original equipment manufacturers (OEMs) complete access to PPG’s library of digital color files. It is also fully compatible with industry-standard color-rendering software, enabling OEM design teams to collaborate with PPG directly, remotely and in real time on the color design process.

The program’s launch is the first step in digitizing the entire color styling process for PPG customers. “Throughout the pandemic, PPG has recognized our customers’ increasing need for digital tools and technologies,” said Federico Menta, PPG Global Technical Director, Customer Development, Automotive OEM Coatings. “Our industry-leading color experts have already used the program to conduct color styling sessions with several major OEM design teams. Many of those customers believe our program offers an effective alternative to managing the color-styling process in person. We believe it will enhance customer intimacy and create an opportunity for a collaborative color-creation process.”

PPG reports that in addition to being a viable substitute for traditional in-person/in-studio color styling, the program can help OEMs realize significant cost savings. “The ability to integrate new color ideas directly into the customer design process allows our customers to extract time and cost from color-rendering activities,” said Rebecca Liebert, PPG Executive Vice President. “There are also other financial benefits associated with the program, including enhanced speed to market.”

Developed by PPG, the digital vehicle model is designed to depict the interaction of color, geometry and light to create authentic renderings of a vehicle’s surfaces. (Photo courtesy of PPG.)

EcoVadis Recognizes Budenheim Ibérica S.L.U. with Platinum Medal

ZARAGOZA, Spain – Budenheim Ibérica S.L.U. was recently rated by EcoVadis and received the Platinum Medal. This rating puts Budenheim Ibérica in the top 1% of all EcoVadis applicants assessed in their overall sustainability performance. Budenheim Ibérica S.L.U. operates as a chemical specialist for fire prevention and is a manufacturer of halogen-free flame retardant additives, with production sites in La Zaida, Spain, and El Puig, Spain.

Budenheim Ibérica S.L.U. increased its sustainability performance result by 10 points compared to the previous year, achieving 77% in total. The EcoVadis Platinum Medal affirms that Budenheim Ibérica S.L.U. is fulfilling customers’ requirements in terms of sustainable environmental, business and social practices.

The EcoVadis CSR rating platform is based on internationally recognized CSR standards such as the Global Reporting Initiative, the United Nations Global Compact, and ISO 26000. Since its founding in 2007, EcoVadis has assessed more than 75,000 companies.

Budenheim Ibérica S.L.U. received the Platinum Medal from EcoVadis. (Photo courtesy of Budenheim Ibérica S.L.U.)

Andy Sharpe, CEO Bühler North America. (Photo courtesy of Bühler North America.)

Bühler Announces Acquisition of Design Corrugating

MINNEAPOLIS – Bühler North America is expanding its service network and offerings with the acquisition of Design Corrugating Companies, a roller mill and other equipment service company based in Taylorville, Illinois. With this move, Bühler now operates seven service centers in the United States, serving grain, oilseed, feed, pet food, and chocolate processors, as well as brewers and distillers, inks and coatings, and other companies that utilize roller mills.

Design Corrugating provides roller mill parts and services, including roll reconditioning, new rolls, and other equipment parts and services, with facilities in Taylorville, Illinois; Oakdale, California; Wichita, Kansas; and Chattanooga, Tennessee. All Design Corrugating locations will become new Service Center sites in the Bühler Customer Service network, and the entire Design Corrugating staff has joined the Bühler team. Existing operations will continue unchanged, utilizing the “pick-up, repair and deliver” model. Bühler will continue to provide parts and services for all makes and models of roller mills.

“For us, this is only the starting point to develop the most comprehensive and value driving services in our industry,” said Andy Sharpe, CEO, Bühler North America. “Today, the installed assets base of many companies is not running as optimally as it could be and consequently, they are wasting energy and raw material and suffering quality and efficiency losses. We experienced that, with our services, we can achieve step change for customers especially when connecting companies to Bühler Insights, our digital platform, they can achieve the highest process transparency based on data.”

“We are excited to now be part of the Bühler service network,” said Brett Poland, General Manager, Design Corrugating, who has become a Bühler team member and continues to lead the former Design Corrugating locations. “The added resources and support that comes with joining the Bühler Team will help us reach new levels of productivity, expand our service offerings, and improve quality to all our existing and future customers,” said Poland.

Digital connectivity, combined with local service centers and technical experts, will enable Bühler technicians to communicate and work on issues with plant operators in real time, using data and connected tools, such as BühlerVision, to deliver a much more proactive and responsive relationship, and maximize operational uptime and efficiency.