Ready to proof -- CLJ 2-22-22

Proofed by KP 2-22-22

KJ proofed on 2-22 and sent correction

Revised 2-23

INDUSTRY UPDATES

According to Song, this version of a fire-retardant coating offers better protection and could be used in other application settings, such as wooden furniture, mining, tunnels and transportation. “Our fire-retardant coating produces a very robust and thermally stable ceramic layer compared to existing coatings, which usually produce a protective layer that is fragile and degrades at high temperatures,” he said.

The fire-retardant coating still has to undergo further testing and refinement before it could be commercialized and put to widespread use, which Song hopes will be within the next three years. The research, which was financially supported by an Australian Research Council Future Fellowship, was published in the journal Matter.

SPRINGFIELD, Australia – A research team, led by University of Southern Queensland Chemical Engineer and Australian Research Council Future Fellow, Professor Pingan Song, has developed a non-toxic, fire-extinguishing coating that could save buildings from being engulfed in flames. Song said lava sparked his idea of a hybrid coating that would melt and then gradually form a flowing but non-combustible ceramic layer when exposed to extreme heat.

“Molten lava is like a viscous flowing liquid but non-flammable,” Song said. “Once cooled, it solidifies to become a ceramic layer that does not support fire. Inspired by this interesting phenomenon, we designed a fire-retardant coating that can create a non-combustible ceramic layer which can offer fire protection for the underlying substrates, just like a fire shield.”

Song said spraying the coating on building materials, such as thermal insulation foam, timber and steel structures, during construction could prevent disasters like the 2017 Grenfell Tower blaze in London. “Polymer foams were identified as the main cause of recent catastrophic disasters, particularly the Grenfell Tower fire,” he said. “Solid wood materials, also widely used in buildings but extremely combustible, can also trigger fires, like the Notre-Dame de Paris blaze in 2019.”

Researchers in Australia Develop Lava-Inspired Fire Protection

Professor Pingan Song leads a research project developing a lava-inspired fire retardant coating. Photo courtesy of University of Southern Queensland.

Mark Your Calendars for the 2022 FOCUS Conference

PLYMOUTH, MI – The FOCUS conference is returning on May 5, 2022, with the theme “FOCUS on the Future.” Presented by the FOCUS Committee of the Detroit Society for Coatings Technology (DSCT), this conference is a staple for paint and coatings professionals in Southeast Michigan and beyond. Held at the Inn at St. John's in Plymouth, Michigan, the FOCUS conference continues to highlight emerging technology, market trends, industry standards, test methods and other topics relevant to the field. A virtual option may be added depending on conditions surrounding the pandemic.

The 46th annual FOCUS conference will host experts and leaders in the automotive paint and coatings industry who will present their latest challenges and developments. Past topics have included application, formulation, regulatory, color development, and testing and evaluation.

Image courtesy of the Detroit Society for Coatings Technology.

Highlights of FOCUS include: a dual track of technical presentations, continuous networking opportunities throughout the day, a poster session showcasing the talents of local university students, a full range of exhibits from industry suppliers, and a networking and cocktail hour sponsored by Axalta Coating Systems.

For regular updates on the conference, visit FOCUS 2022 online at www.dsctfocus.org.

EMU Announces Online Certificate Program in Polymers and Coatings

YPSILANTI, MI – Eastern Michigan University (EMU) announced a fully online graduate certificate program starting Fall 2022. Responding to the changing landscape of higher education and needs for training and skill acquisition through remote education, this program is expected to appeal to many employees working in the paints, coatings and adhesives industries, as well as their raw material supplier companies. Students can complete this 15-credit-hour (five courses), asynchronous online program at their own pace, without having to leave their job or commute long distances.

This program is ideal for new entrants to the industry or to the experienced technicians, chemists, sales and marketing, or technical service personnel within the industry; it offers a unique opportunity for skill development and career growth. The certificate holders will have the option to transfer all their credits to the master’s degree program in polymers and coatings at EMU. For more information, visit the EMU webpage or contact the faculty adviser Professor Vijay Mannari at Polymers_Coatings@emich.edu.

Photo: Nutthaseth Vanchaichana, iStock/Getty Images Plus via Getty Images.

Superior Materials Announces Passing of Frederick Kafka

GARDEN CITY, NY – Superior Materials Inc. announced that Frederick Kafka passed away Saturday, January 29, at the age of 97 due to complications from COVID-19.

Born in Vienna, Austria, Kafka immigrated to the United States with his family in 1938. He was drafted into the U.S. Army in 1943 during World War II and was in battle in various campaigns in Italy, including the PO Valley Campaign. Among many decorations, he received a Purple Heart and a Bronze Star. Upon his return to New York, he completed his degree in chemical engineering from Columbia University and joined Superior Materials Inc. in 1948 as an engineer, working alongside his father-in-law Benjamin Joachim and brother-in-law Meyer Budman. These three men at the helm of Superior were true pioneers in developing the industrial use of kaolin and attapulgite clay, among other raw materials. The Superior team invented the name ASP®, which is known globally as the hydrous nomenclature for what is now the Kaolin group of BASF.

Kafka along with Meyer built Superior’s sales, and the company grew. Later on, both of Kafka’s sons and Meyer’s son joined the business. Today, it has evolved into a fourth-generation, privately held chemical distributor covering 26 states for a variety of specialty chemicals.

Kafka was actively involved in multiple trade associations and for years provided photographs for various publications of meetings and outings as a volunteer. He worked for well over 50 years at Superior and remained interested in the business for the remainder of his life. He leaves his wife of over 75 years, Mindy, three children, six grandchildren, and three great grandchildren. He received a Paint Pioneer award from the MNYCA years ago and was very active in the organization. He had a reputation for being honest, intelligent and a true pioneer in the field of raw materials.

Photo: diephosi, iStock/Getty Images Plus, via Getty Images

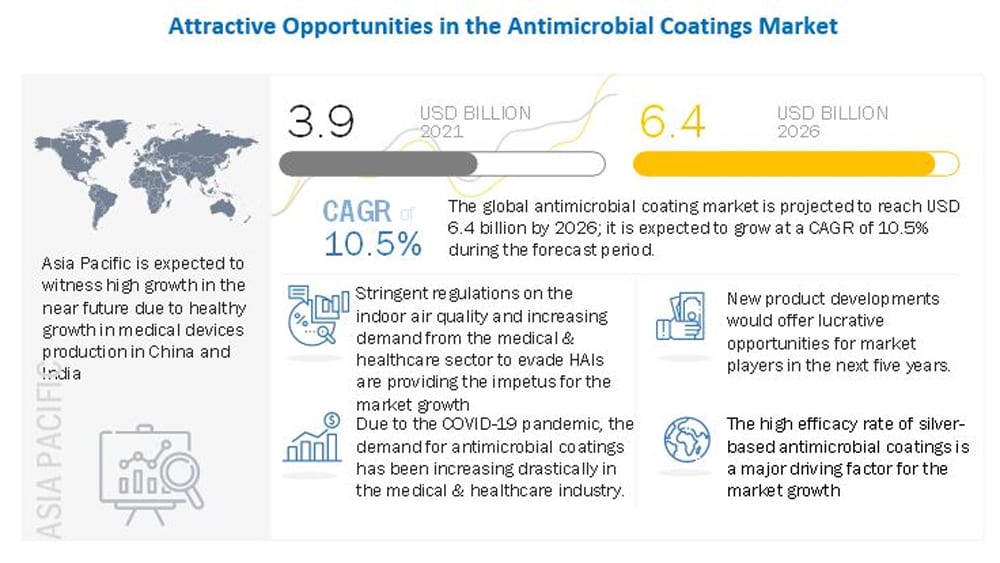

Study Predicts Antimicrobial Coatings Market To Reach $6.4 Billion by 2026

PUNE, India – MarketsandMarkets™ announced the release of a new study that predicts the global antimicrobial coatings market size will grow from $3.9 billion in 2021 to $6.4 billion by 2026. The study predicts a compound annual growth rate of 10.5% for the antimicrobial coatings market. The growth is attributed to the increasing use of antimicrobial coatings across several industrial applications to ensure safety from bacteria, pathogens and other microbes.

The study reports that by type, the silver-based segment accounted for the largest share in the overall antimicrobial coatings market. It is used widely due to properties such as a high efficacy rate, long-lasting effect, durability and strength, among others. The higher efficiency and low toxic nature compared to other types of antimicrobial technology support this growth. The silver-based segment is experiencing increased penetration in the medical and healthcare, protective clothing, food and beverage, and HVAC system applications.

The medical and healthcare sector is estimated to be the leading consumer of antimicrobial coatings. This sector led the overall antimicrobial coatings market in 2020, both in terms of value and volume. In the medical and healthcare industry, growing concern about hospital-acquired infections (HAIs) and their impact is a major driving factor for the antimicrobial coatings market. There has been a significant increase in the patient pool across the globe due to the COVID-19 pandemic. For the treatment of these patients, temporary hospitals and facilities have been established in several countries, where care has been taken to avoid the spread and growth of the COVID-19 virus and other bacteria on surfaces. These temporary and existing healthcare facilities are applying antimicrobial coatings on surfaces such as door handles, trails, beds, healthcare instruments, and medical devices used for treatment.

According to the study, North America is projected to have the largest share in the global antimicrobial coatings market, in terms of both value and volume, from 2021 to 2026. The North American antimicrobial coatings market is driven by rising demand from the medical and healthcare sector to inhibit the growth of bacteria and microbes causing HAIs. In North America, the United States has been severely impacted by the COVID-19 pandemic compared to Canada and Mexico, which resulted in a significant increase in demand from the medical and healthcare application sector. Additionally, due to stringent regulations pertaining to indoor air quality, HVAC system manufacturers are incorporating antimicrobial coatings on surfaces to ensure the required air quality by inhibiting the growth of mold and bacteria.

Image courtesy of MarketsandMarkets™.