Ready to proof -- Clare 4-20-21

Edited by KP on 4-21-21

Proofed by KJ on 4/21

Clean

INDUSTRY UPDATES

Based on resin type, the market is segmented into polyurethane, acrylic, epoxy and others. According to the study, the polyurethane segment dominated the market by about 36.12% in 2019, due to the rising use of polyurethane in topcoats. Greater flexibility along with high impact, corrosion and heat resistance make this resin the most suitable for its use in basecoats and clearcoats, making this segment the most dominant in the market.

Based on product type, the market is segmented into primer, basecoat, electrocoat and clearcoat. The clearcoat segment had the largest share of the market in 2019, at 34.8%, while the report expects the basecoat segment to grow at the fastest CAGR of 6.5% during the forecast period.

By end use, the market is segmented into commercial OEM, light vehicle OEM and automotive refinish. Light vehicle OEM dominated the market in 2019, acquiring about 42.9% of the global market, and is likely to keep dominating the market in the upcoming years. Rising demand for passenger cars in developing countries, such as Thailand, Singapore, China, India and Brazil, is expected to boost the growth of this segment. Additionally, increasing per capita income, and rapid urbanization and population growth are adding to market growth. The report predicts that the automotive refinish segment will grow at the fastest CAGR of 6.8% during the forecast period of 2020 to 2027.

At a regional level, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East and Africa. North America was the dominant regional market in 2019, with a revenue share of about 46.8%, whereas the Asia-Pacific market is expected to grow at the fastest pace with a CAGR of 6.4% during the forecast period. Countries such as Thailand, Indonesia, India, South Korea and China are experiencing a gradual rise in the use of automotive coatings. China, due to rising purchasing power and a high economic growth rate, is expected to remain the largest market in the Asia-Pacific region during the forecast period. A global production capacity shift from the developed regions to the developing countries is expected to enhance further growth.

BRAMPTON, Ontario — According to a new market study, the global automotive coatings market is estimated to grow from $17.82 billion in 2019 to $27.64 billion by 2027, increasing at a compound annual growth rate (CAGR) of 5.7% during the forecast period of 2020-2027. The report, Automotive Coatings Market by Technology, by Resin, by Product, by End Use OEM and by Region: Global Industry Trends, Dynamics, Competitive Insights and Forecast Analysis, 2021–2028, is published by ReportCrux Market Research.

Based on technology, the market is segmented into waterborne, solventborne and UV-cured technologies. The report predicts that waterborne technology will grow with the fastest CAGR of 6.8% during the forecast period of 2020 to 2027.

Report Predicts Global Market for Automotive Coatings to Reach $27.64 Billion by 2027

Photo: YinYang/E+, via Getty Images

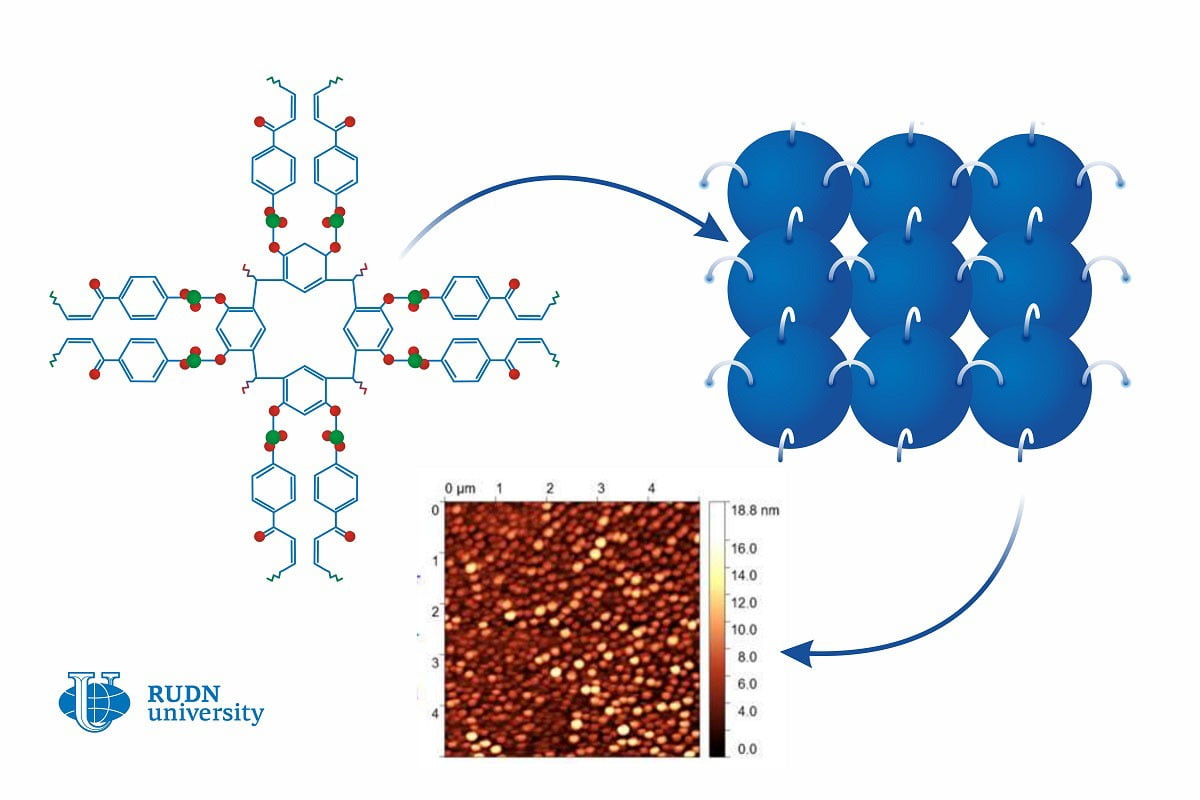

Chemist at Russian University Develops Nanofilm from Calixarene

MOSCOW — A chemist from RUDN University in Moscow, Russia, together with colleagues, created a new type of two-dimensional nanofilm from an organic material called calixarene. The invention can be used as a protective coating in electronics and as a part of molecular filters. The researchers also suggested a way of increasing the durability of such films with UV radiation.

"These 2D organic films can be used to create protective hydrophobic or anti-corrosion coatings for organic electronics, or to develop molecular filters," said Alexey Kletskov, a Candidate of Chemical Sciences, and a researcher at the Joint Institute for Chemical Research, RUDN University.

The team used the Langmuir-Blodgett method to construct a thin film from single molecules. The method had been developed especially for molecules that have both hydrophilic and hydrophobic parts. When put in water, molecules like this align on the surface with their hydrophobic parts turned up. After that, they are pressed with special plungers, and when the required density is reached, the film is moved onto a solid base.

To strengthen the film, the team used UV radiation. It has enough energy to break down hydrocarbon chains that bind the outer and inner rings of each molecule together. First the chains are broken, and then they bind again, but this time with loose ends from other calixarene molecules. As a result, all molecules in the film become closely tied together.

The team studied the structure of the films using an atomic-force microscope and found that the efficiency of UV radiation correlates with the length of the chains in the original macromolecules. Molecules with short chains formed more stable films, and in the case of long-chain molecules, UV radiation caused the films to have irregular structure with clusters. Therefore, UV light was found to not always be beneficial for film quality. Depending on the molecule structure, it can reduce the water-repellent properties of a film or have no considerable effect at all. It is an important factor to consider when using the films as hydrophobic coatings on different surfaces, from displays to construction coatings.

The results of the study were published in the Materials Today Communications journal.

Calixarenes are large, bowl-shaped organic molecules that consist of several rings. The outer ring of the bowl is hydrophilic. The innermost ring is hydrophobic. Calixarenes are additives, and play a role in the synthesis of ethylene and propylene polymers. Scientists from Belarus and Russia, including a chemist from RUDN University, suggested a new way of using them. They developed 0.8-1.5 nm thick calixarene-based films that can work as water-repellent coatings.

Image courtesy of RUDN University.

Paint Recycling Program Launched in Washington State

SEATTLE — A new paint-recycling program that began on April 1, 2021, in the state of Washington allows households and businesses to recycle leftover paint, stain and varnish conveniently and sustainably. The program is operated by PaintCare, a nonprofit organization created by the paint industry through the American Coatings Association (ACA) to manage leftover paint in states that have enacted paint stewardship laws. PaintCare will provide more than 200 drop-off sites across Washington, which include paint retail stores and locally managed government facilities.

How It Works

A small fee on the sale of new paint — called the PaintCare fee — funds all aspects of the program including paint collection, transportation, processing and public education. The PaintCare fee in Washington is the same as in neighboring Oregon, and varies by container size: $0.00 for half pint or smaller; $0.45 for larger than half pint up to smaller than one gallon; $0.95 for one gallon up to two gallons; $1.95 for larger than two gallons up to five gallons.

PaintCare makes it convenient to recycle leftover paint by partnering with local government facilities and paint retailers near residential neighborhoods. These locations make it easy for households and businesses to find the nearest drop-off site by visiting PaintCare's online site locator.

Most PaintCare sites accept both latex and oil-based architectural paint products, including paints, stains and varnishes. Paint must be dropped off in its original container with its original manufacturer's label. A full list of products accepted by the program is available on PaintCare's website. All sites accept a minimum of five gallons of paint from each customer; some sites may accept more.

Washington's program follows similar paint stewardship laws in nine other states and the District of Columbia, all built on a model mediated by the Product Stewardship Institute (PSI) over a decade ago. Passage of the Washington paint stewardship law was made possible by a collaboration among multiple stakeholders, including Washington's Department of Ecology (Ecology), PSI, the Northwest Product Stewardship Council (NWPSC) and Zero Waste Washington. The new program is expected to manage more than 1.3 million gallons of paint in its first year.

"We are so pleased that paint recycling is now a reality for Washington State," said Megan Warfield, Ecology's Paint Program Lead. "This program is a big step forward for product stewardship in the state. It’s also a testament to the dedication and perseverance of a diverse set of Washington stakeholders from government, industry and nonprofit communities."

It is estimated that about 10% of all household paint goes unused. When dumped in the trash or down the drain, leftover paint can contaminate the environment. Although most leftover paint can be reused, recycled into new paint, or repurposed into other products, much of it is trashed because people do not know where to take it or it's not convenient.

"The PaintCare program is an excellent example of producer responsibility in action and what can be achieved when producers engage with governments, recyclers and others in a collaborative process," said Scott Cassel, Chief Executive Officer and Founder, PSI. "Going forward, the Washington program will divert millions of gallons of paint from landfills, collectively save local governments across the state millions of dollars each year, increase environmental benefits, and boost the green economy."

PaintCare helps ensure the "highest, best use" for paint collected in the program, including giving away good-quality material as is, recycling it or putting it to another beneficial use. Most of the paint PaintCare receives is latex-based and can be remixed into recycled paint products by processors. To date, PaintCare has processed more than 46 million gallons of paint nationally and saved state and local governments millions of dollars.

"There has been tremendous effort to create a paint recycling program in Washington state," said Jeremy Jones, West Coast Program Manager, PaintCare. "We've been building and running paint recycling programs in other states for more than 10 years, and will leverage this expertise in Washington to deliver a program that meets the needs of households and businesses."

Washington's paint recycling program was made possible under the paint stewardship law (SHB 1652), which was passed by the Washington State Legislature and signed into law by Gov. Jay Inslee in 2019. The law ensures that everyone who produces, sells and uses paint work together to manage its entire life cycle.

Photo courtesty of PaintCare.

NACD Expresses Concerns with Proposed EPA TSCA Fees Revisions Rule

ARLINGTON, VA — The National Association of Chemical Distributors (NACD) recently submitted comments in response to the U.S. Environmental Protection Agency's (EPA) Proposed Rule on Fees for the Administration of the Toxic Substances Control Act (TSCA), docket EPA-HQ-OPPT-2020-0493.

NACD reports that it has substantial concerns with EPA's proposed rule because it proposes to nearly double the cost of risk evaluations unjustifiably and adds three unnecessary new fee categories for EPA activities. Furthermore, NACD states that the proposed rule fails to provide adequate information on and justification for EPA's proposed cost increases.

"Financial predictability in business is always important; but today, as so many businesses are fighting for their very existence because of COVID-19-related economic challenges, this is even more critical," said Eric R. Byer, NACD President and CEO. "NACD and our members urge EPA to avoid placing oppressive financial burdens on the chemical industry through new fee categories and increasing fees by significant amounts without justification, as this proposed rule would do."

NACD is asking for predictability, flexibility and protections for small businesses in whichever fee structure EPA chooses. NACD recommends EPA expand the timeline for manufacturers to exit the market, enhance predictability of payments by providing fee estimates, establish fee caps for small business concerns, and provide an in-depth economic analysis of the agency's costs to help industry respond to whether the proposed cost increases are appropriate.

When TSCA was first being negotiated, the business community supported industry fees as an effective and fair way to support the EPA's activities within reasonable limits. It was critical to industry, however, that the fees be properly justified, the agency's costs be transparent, and the fees be used to match resources with actual needs. NACD stated that it appreciates EPA's efforts to establish a clear and fair system for administering TSCA user fees, but the proposed rule does not meet this objective. The proposed unjustified and excessive increases will pose significant hurdles for chemical companies, especially small businesses.

Photo: Skyhobo/E+, via Getty Images

Eastern Coatings Show Issues Call for Papers

ATLANTIC CITY, NJ — Organizers of the Eastern Coatings Show have issued a call for papers. The show is set to take place Nov. 17-19, 2021, at Harrah's Resort in Atlantic City, New Jersey,

The Eastern Coatings Show seeks submissions from academia, government and industry presenting novel research results in all aspects of coatings. It is the goal of the Eastern Coatings Show to further the advancement of coatings technology through these speaker platforms. The show is intended to offer educational and technical presentations to create an understanding of the theory, the science, the manufacturing and the marketing of coatings to highlight the improvement of coatings performance and functionality beyond traditional expectations.

Speakers will be presenting on Nov. 18 and 19, 2021. The ECS Technical Committee will be responsible for coordinating all speakers and the agenda. The criteria for the presentations are listed below:

Abstract, Biography and Picture: The ECS Technical Committee requires an abstract for the presentation, biography and picture of the speaker to be forwarded to Carl Sullivan. Due to the change of date for the show, the deadline for submissions is now May 31, 2021. To be considered for a speaker slot, all three items for the abstract must be received. Acceptance letters will be sent by June 18, 2021. The presentation schedule will be published no later than June 30, 2021.

Presentations: The PowerPoint presentation should be e-mailed or sent via CD or USB memory stick to csullivan@stanchem-inc.com on or before Aug. 17, 2021. Organizers of the show plan on distributing copies of presentations to the attendees, so prospective speakers should include their permission or denial to disseminate the presentation.

Content: The ECS Technical Committee will be reviewing the presentations based on their technical content and contribution. Committee members are trying to make the presentation format as close to a short course as possible. Therefore, presentations that are geared towards technical, and teaching will be given priority. They realize that company logos will be on the slides. However, they do not expect the presentations to be a commercial for the speaker's company nor laden with trade names. Presentations should be edited for this before sending, as the Technical Committee will ask speakers to do so if a presentation is deemed too commercial.

Time: Presentations should be no less than 20 minutes and no longer than 30 minutes.

Pflaumer Brothers Innovation Awards: To further industry innovation, Pflaumer Brothers of Ewing, New Jersey, is sponsoring awards to honor and recognize the top two technical papers showing the most outstanding technical innovations. The Pflaumer Honors for Innovation Award for the Most Outstanding Paper is an honorarium for $2000. The Pflaumer Honors for Innovation Award for Outstanding Paper is an honorarium for $1000.

For more information, e-mail Carl J. Sullivan, Ph.D., Technical Committee Chairman, at csullivan@stanchem-inc.com.