Ready to proof -- Clare 04/6/22

KJ proofed on 4/13 and sent corrections to Clare

CLJ revised on 4/13

Ready for author - clean

Poor Cure?

It's Not Always

the Coating

Photo: proxyminder, iStock/Getty Images Plus, via Getty Images

By Bob Blandford, President, Miltec UV, Stevensville, MD

Getting a complaint is never fun. Your chemists work hard to develop just the right formula for a coating or adhesive and when it fails to cure properly, peels or separates from a product, either during or after the manufacturing process is complete, it's your company that bears the brunt of the responsibility and whose reputation is tarnished.

While a quality inspector periodically checks samples during the beginning, middle and end of the process, and production operators do radiometer testing, the end product must be uniform and the cure consistent, or what appeared to be correct at the beginning of a run can look very different at the end. If you're lucky and you catch a problem, you'll only have to explain a small amount of waste to your customer, but if the product ships and the quality is not up to the customer's expectations, you're at risk of having them go somewhere else.

Customer loyalty isn't what it used to be, and it is 5-25 times more expensive to acquire a new customer than it is to retain an existing one.1

So how do you ensure that your customers are happy and provide a uniform and consistent run? Before going back to the old drawing board, start by looking at your UV-curing equipment. Four main focus areas influence and assist a UV system to run properly:

- Lamp cooling and airflow

- Reflector performance

- Preventive maintenance

- Proper light shielding

Paying close attention to each of these in both lamp- and microwave-powered UV systems can solve ongoing problems with your UV-curing process, or help prevent issues and ensure your system is running at peak performance levels.

Cooling and Airflow

UV lamps operate at very high temperatures (at around 800 °C or 1,500 °F bulb surface temperature) in order to maintain a consistent, fully developed mercury plasma state inside the UV bulb. More advanced UV lamp systems require a cooling system that not only maintains the lamp stability in that range but also protects the integrity of the metal structure in which the lamp is operating.

The most common method to cool a UV lamp is with air flowing through its housing and across the UV bulb and reflector. Lamps have a "cooling window" when it comes to proper air cooling, and it is critical that the lamp is not over or under cooled. The amount of air flowing over the UV bulb will depend on the power level you operate the UV lamp.

Most modern UV lamp systems are powered by variable power ballasts that deliver a range from 20% to 100% power to the lamp. Such a wide power adjustment range allows the lamp to be changed from about 130 watts/inch up to about 650 watts/inch.

For some UV systems, the power setting is adjusted by the front panel controls, but for other, more sophisticated UV systems, the lamp power is automatically adjusted as a function of line speed via a 0-10 VDC or 4-20 milli-amp signal provided by the customer. As the lamp increases in power, it requires more cooling air delivered over the UV bulb to prevent the UV bulb from overheating. Conversely, as the lamp power is reduced, the cooling air must be reduced to ensure the lamp is not overcooled.

The cooling system must adjust automatically to match the lamp power and heat load to maintain the lamp's stability and ensure that it operates within its proper temperature range. Lamps operating in an "over-heated" condition will result in shortened lamp life and possible lamp swelling or warping, adversely affecting UV output and uniformity.

Lamps that operate in an "over-cooled" condition will suffer from shortened lamp life and low UV output as well. When a lamp is over cooling, it cannot develop the correct voltage, and the current (amps) remain high, putting adverse wear on the electrodes over time. In most cases when the lamp is over cooled the mercury plasma will become unstable, and the lamp will inadvertently extinguish. Only when a lamp is operating within the correct cooling parameters consistently will maximum lifespan of the UV bulb be realized, as well as consistent UV output from the UV bulb be achieved.

Reflector Performance

Another critical part of any UV system that must be maintained to ensure a healthy UV-curing system is the condition and performance of the reflector, which typically is in the shape of a semi-elliptical or parabolic geometry that wraps around the upper half of the bulb and extends the entire length of the UV bulb.

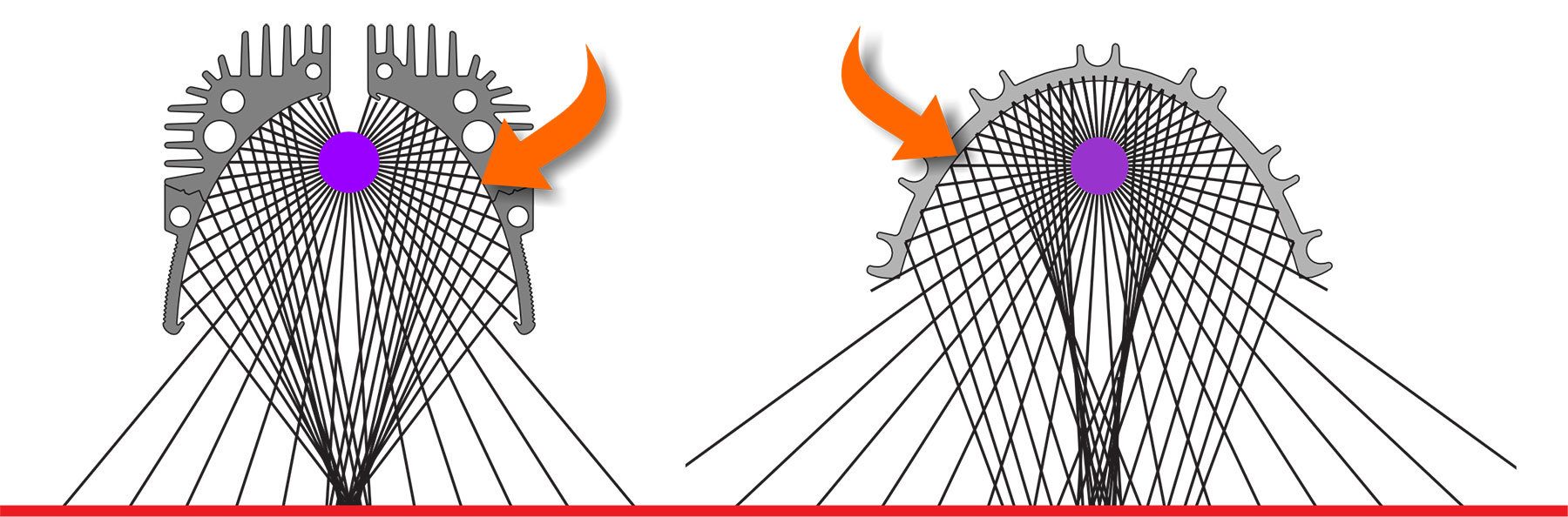

The lamp reflectors are an essential part of the UV lamp system because they are typically responsible for reflecting about 65% of the UV energy emitted from the UV bulb onto the customer's product. The curved shape of the reflectors is typically designed to concentrate (or focus) the light rays to a very small area, creating extremely high UV peak irradiance at the customer's product, which is one of the keys to UV curing. When the reflectors are not cooled properly, they can warp and wrinkle due to thermal expansion (Figure 1).

FIGURE 1 ǀ An overheated reflector causes the UV light pattern to scatter or diffuse, which can negatively affect the curing process.

Reflectors that lose their curved shape will cause the light ray pattern that reflects from the reflector toward the customer's product to become scattered or diffused, negatively impacting its ability to cure (Figure 2)

FIGURE 2 ǀ Conventional light ray patterns used in most UV-curing systems.

It is vital that the curved shape of the reflector does not change during lamp operation in order to maintain these UV light ray patterns. In addition, when reflectors become dirty, contaminated or dulled over a period of usage, the % reflectivity will reduce significantly, reducing the UV energy and intensity delivered to the customer's product.

Poor reflector conditions will result in customers producing an un-cured product. The reflector is considered a consumable part for all UV systems and is considered a component that requires attention and maintenance (or periodic cleaning) to help ensure good, consistent UV output from the UV lamp system.

Some UV systems use replaceable reflector liners, which are normally a thin polished aluminum material with a protective coating (which looks much like a conventional mirror finish) and typically pre-curved and cut to fit into a reflector holder inside the lamp housing.

More sophisticated UV lamps use "cold mirror" reflectors, which are also thin, pre-curved and cut aluminum or glass reflectors that are held in a holder of some type inside the lamp housing. Cold mirror reflectors have special coatings applied to the reflective side of the reflector substrate that are designed to efficiently reflect UV light but absorb the IR energy (heat) emitted by a UV bulb. Cold mirror reflectors will reduce the heat load on the customer's product as it travels under the UV lamps, thereby, reducing the possible thermal damage to the substrate or expansion and shrinkage of metal, wood and plastic substrates.

Regardless of the reflector type, it is important that the reflector condition is maintained to remain clean with a shiny appearance. If the reflector begins to look dull or dirty, that's an indication that it needs to be either cleaned or replaced. Reflectors can be cleaned using a lint-free cloth and isopropyl alcohol, or a surface cleaner that does not leave a film. Cleaners that contain ammonia are not recommended.

If, after cleaning, the reflector still appears to be dull or dirty, then it should be replaced. In almost all cases, a dirty or dulled reflector will have more impact on UV output reduction than an old and poor-performing UV bulb. Measuring your UV output will also help diagnose a poor-performing reflector.

Preventive Maintenance

Most UV lamps operate in industrial environments, which are typically less than ideal conditions. It is important to try to keep the lamp as clean as possible to help ensure consistent UV output and prolong its useful life. Neglected lamps will age, fail prematurely and suffer from low UV output.

The simplest way to keep your UV bulbs clean is by cleaning them with a designated UV glass bulb cleaner and a lint-free cloth. The frequency will vary depending on the environment in which they are operating. Dirty and contaminated UV bulbs that operate for prolonged periods are more prone to overheating, and then swelling or warping.

If a UV bulb swells or warps, this will negatively impact the UV peak irradiance output of the lamp and curing performance of the UV lamp system (Figure 3). Once a UV bulb appears swollen or warped, this is a sign that the UV bulb should be replaced. If air filters are used to help keep the lamp cooling air clean (which is common for microwave-powered UV lamp systems), then it is important to change these filters on a periodic basis to help ensure the lamp cooling air that enters the lamp housing and flows across the UV bulb (and reflector) is clean.

FIGURE 3 ǀ A swollen lamp.

Maintaining clean air filters will also help ensure that the volume of air delivered to the lamp is maintained within the required specification. Operating a UV lamp system with dirty and/or clogged air filters will almost always result in over-heated UV bulbs and a significant reduction in UV bulb life, and this will require more frequent UV bulb changes.

The heart of any UV system is the expensive power supply that drives the UV lamp. Whether a conventional iron and copper core ballast or a solid-state power unit is used, the proper volume of filtered cooling airflow delivered to the ballast is critical to any ballast's health and life expectancy, and other electrical components inside the ballast enclosure. Power supplies operating in a dirty or over-heated environment will deteriorate or fail prematurely, resulting in low UV output or lost production.

Making sure you maintain a clean air filter and the proper amount of airflow to the ballast will ensure your ballasts are properly cooled and kept clean. Air filters should be replaced as often as needed, depending on the environment. In the event the ballast and other internal power supply components (such as capacitors) become coated with dirt or dust (like shown in Figure 4), it is highly recommended to do two things: 1. Check the air filter and replace it if needed; 2. Blow out the ballast and all other internal components with clean, dry, compressed air, and then vacuum out the settled dust.

FIGURE 4 ǀ Dusty internal power supply components.

Light Shielding

The last ingredient to maintaining a healthy UV-curing system involves the light shielding. The primary purpose of light shielding is to protect personnel from any direct UV light exposure. Adequate light shielding in and around the UV lamp housing will protect the lamp module components and the production machine to which it mounts. The more light that can be seen by operators, the more dangerous the exposure.

A properly designed light shield will prevent any machine hardware near the UV lamp from reaching unsafe temperatures or deterioration from direct UV exposure. The secondary function of the light shield is to support the UV lamp housing in a way that it will efficiently cure the customer's product. If the light shielding is removed from the machine for maintenance to the production equipment, it is critical to install the light shielding in the same position and location on the machine to ensure the lamp is positioned in the correct location and orientation with respect to the customer's product that is being cured.

The third function of the light shield is its contribution toward proper air cooling. Some light shields may have air intake vents or air louvers to allow air to enter the light shield for lamp cooling, substrate cooling and/or light shield cooling. If the air intake vents become clogged with dust or dirt, this can cause an increase in temperature of the UV lamp, light shield and the customer's substrate. The result can be poor lamp performance, short bulb life or overheating the customer's substrate.

Part of the routine preventive maintenance schedule should be to periodically clean out these air intake vents (or louvers) on the light shield with brushes and a vacuum, or blow them out with dry, compressed air.

Conclusions

As you can see, by keeping all the components of your UV curing system clean, cool and maintained, you can expect uniform and consistent cures, fewer issues, reduced scrap and happy customers.

For more information, click here.