Ready to proof 10/5

KJ sent corrections to Clare on 10/11

CLJ revised on 10/11

Ready for author

Best Practices for paint Color Formulation

Photo courtesy of Konica Minolta Sensing Americas.

By Mark Lombardi, Technical Support Manager, Konica Minolta Sensing Americas, Inc., Ramsey, NJ

When formulating color, everything, from a supplier using a new base, to water from a different location, will influence the end color. The paint and coating color formulation process requires standardizing conditions and procedures to match color standard efficiently. Color formulation involves defining requirements and methods while also identifying variables within the environment or production process that could influence the color formulation results. In addition, color measurement instruments such as spectrophotometers and sophisticated color formulation software, such as Colibri®, are essential for quantitative analysis to help achieve the right color with minimal time and waste.

Benefits of Formulation Software and Spectrophotometers

These tools can provide increased productivity, reduced cost and improved quality. Companies can:

- Improve quality by quantifying the color of the product;

- Use data to evaluate trends in production;

- Improve quality control of incoming raw materials;

- Reduce cost with waste due to off-color batches;

- Reduce colorant inventory by incorporating a standardized colorant set;

- Enhance productivity by getting to the acceptable color quicker, getting verification of customer requirements and streamlining production.

We recommended specifying the color measurement and visual evaluation conditions before proceeding with the color formulation process.

Color Measurement Tools

Various color measurement instruments and color formulation software are available to coatings formulators. Two such instruments are the benchtop CM-36dG spectrophotometer and the portable CM-26dG spectrophotometer.

The CM-36dG unit is a high-precision and high-reliability bench-top instrument capable of measuring color either in reflectance or transmittance. With an integrated, ISO 2813-compliant 60° gloss sensor inside, color and true gloss can be measured simultaneously. The spectrophotometer utilizes the patented and proven Numerical UV Control (NUVC), unsurpassed technology for UV adjustments when measuring samples that contain optical brighteners. The optional Wavelength Analysis and Adjustment (WWA) compensates for slight shifts in measurement values due to external factors. It assures the highest accuracy and repeatability levels for this class of instrument when done together with annual calibration and maintenance (Figure 1).

FIGURE 1 ǀ Spectrophotometer CM-36dG.

Photo courtesy of Konica Minolta Sensing Americas.

The CM-26dG spectrophotometer is the next generation of portable sphere spectrophotometer with an integrated 60° gloss sensor, allowing distinct color and appearance measurements within one instrument. Its horizontal alignment can fit into narrow spaces and is convenient for high-precision color and gloss measurement. This unit offers unprecedented accuracy/inter-instrument agreement (IIA), usually found in laboratory-grade instrumentation. The CM-26dG offers features to improve workflow, eliminate waste/rework, and cost savings on color-related processes (Figure 2).

FIGURE 2 ǀ ǀ Spectrophotometer CM-26dG.

Photo courtesy of Konica Minolta Sensing Americas.

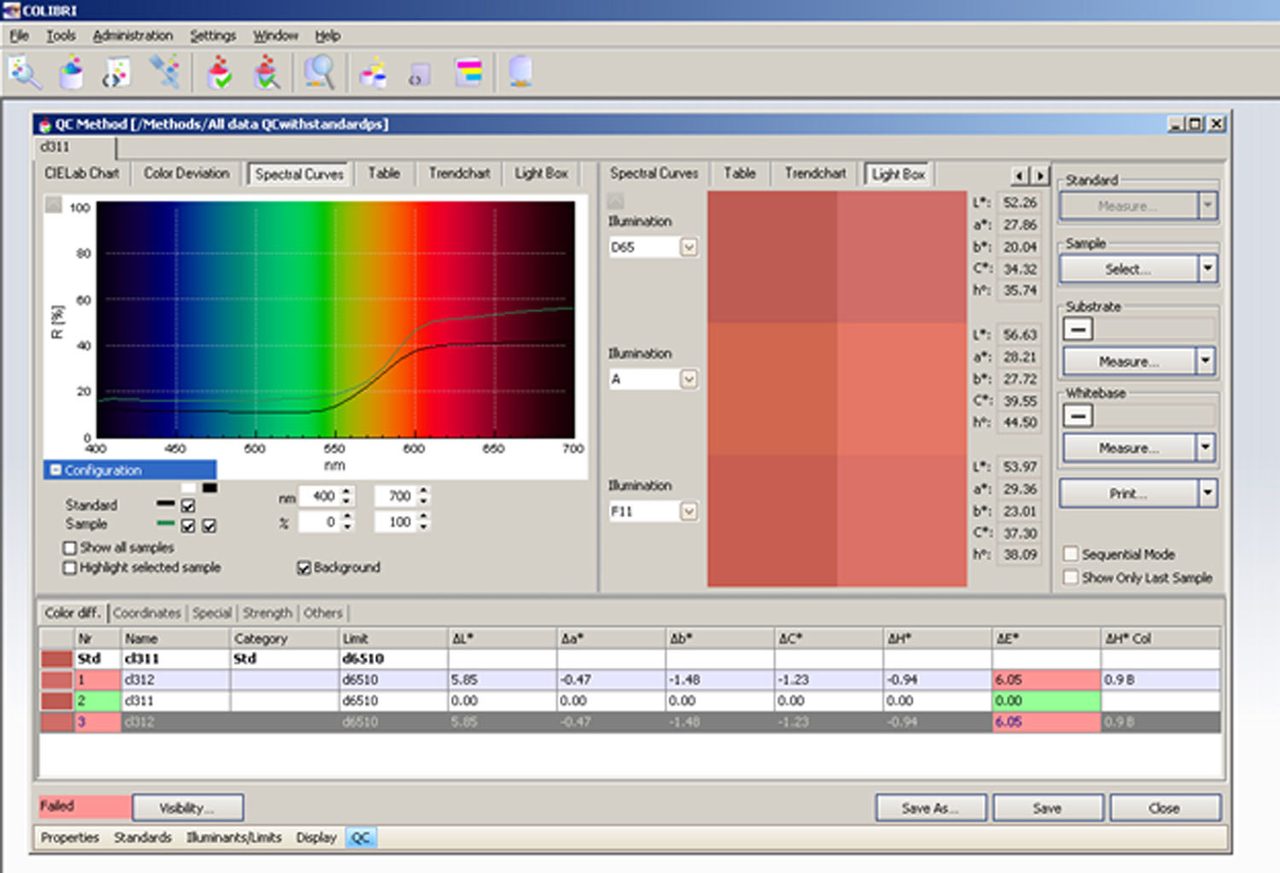

Colibri software is designed to work with a wide variety of our company’s bench-top and handheld spectrophotometers. It is an efficient, powerful and easy-to-use modular software suite that can handle all your needs from color quality control to formulation. Colibri is an SQL-based modular platform, which allows users to choose the modules and add-ons required for their business’s needs.

Color Measurement

There are a variety of factors involved when measuring color (Figure 3), which include:

- Optical/measurement geometry

d/8 (sphere-based illumination)

45/0 (directional illumination).

- Standard illuminants

D65

A

F11

- Observer

2 degree

10 degree

- Color space, such as

Hunter L, a, b

CIE L*, a*, b*

L*, C*, h*

- Color difference equations and tolerancing, such as

DE*abDE*94

DE*00

CMC

- Sample preparation and presentation methods, such as

Same substrate material;

Averaging measurement,

and if so, how many

FIGURE 3 ǀ ǀ In this screen shot, the technician can easily see the data under different illuminants and the spectral curve data, as well as see the L*a*b* values and Delta E.

Photo courtesy of Konica Minolta Sensing Americas.

Visual Evaluation

For visual evaluation, the following parameters should be considered:

- Light booth type and model, for example GTI CMB-2540;

- Viewing angle: Flat or 45/0;

- Light sources, such as D65 Daylight, Cool White Fluorescent, Incandescent A, LED 3000K.

Once these conditions are determined, a standardized color formulation process can begin.

Color Measurement and Evaluation Best Practices

First, define the color standards internally or externally between customers and suppliers. Next, measure the color you would like to match for the finished product using a color-measuring instrument and record its color values. Upload the standard’s color values to a color formulation software for formula calculation that best matches the standard.

Using the calculated formula, create a sample of this color in small batches. After sample preparation and, if necessary, conditioning of samples, use a color measuring instrument to measure and compare its color values as well as reflectance curve against the standard.

Compare the sample against the standard visually within a controlled environment using a lightbox to check for any noticeable inconsistencies. To obtain accurate results and identification of metamerism, we recommend performing the comparison under three different light sources.

Save the ideal formula in the color formulation software to use in future batches. Color formulation software may calculate several formulas based on preset parameters like best color match or best cost. It is essential to select the formula that best matches the standard color under defined illuminants and light sources through instrumentation and visual examination. Likewise, it would help if you considered a particular colorant that the user feels works best together previously.

Color Formulation Conditions and Procedures Best Practices

By implementing a standardized color formulation process and establishing a controlled environment,

you can effectively match color standards with minimal waste and time. Some best practices include:

- Maintain your equipment to ensure it is in proper working condition.

- To ensure consistency, monitor the strength of incoming pigments or dyes.

- Establish appropriate weighing methods for pigments, substrates, dyes or auxiliaries.

- Calibrate color measurement instruments and weighing scales at scheduled times for accuracy and optimum performance.

- Maintain the lightbox used for visual evaluations with lamp replacement.

- Specify a fixed room temperature to avoid causing a drift in the color of your samples.

- Standardize procedures from the start to end, which includes the creation of samples for measurement, mixing samples, the flash time after mixture and oven temperature, and time for drying.

To learn more, visit https://sensing.konicaminolta.us/us/products/colibri-color-software.