Ready to proof -- CLJ 09/10/21

Sent to author or 9/14

New Ultra-Thin Pigment Technology

© by Schlenk Metallic Pigments

New pigment technology using ultra-thin aluminum substrates can be used to produce highly opaque, chromatic effect coatings. With the individual effect pigments it is possible to realize color shades that were previously only known from (semi-) precious metals.

By Adalbert Huber, Vice President Research and Quality Control; and Frank J. Maile, Global Technical Director, Business Unit Effect Pigments, Schlenk Metallic Pigments GmbH, Roth, Germany

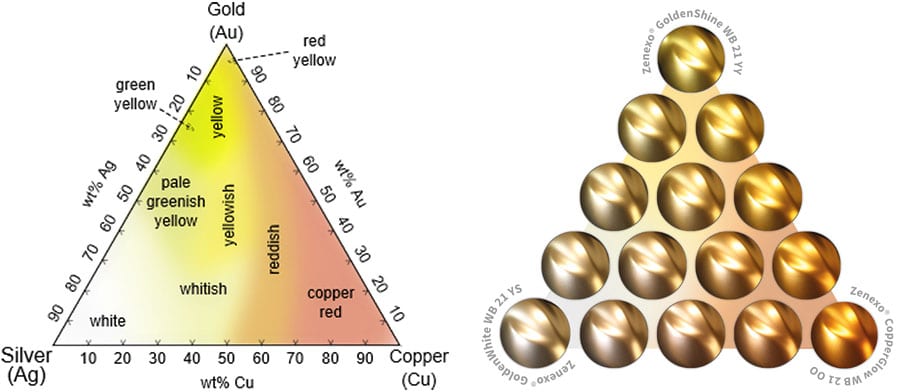

Gold has always fascinated people because of its unique appearance.1 The yellowish metal shows high hiding power and shine even in very thin layers. In addition, it has an extreme light-dark flop. By mixing copper and silver, different color impressions can be achieved. These color shades can now be imitated in coatings, printing inks and plastics with new ultra-thin pigment (UTP)-based effect pigments.2 For this purpose, Schlenk has transferred the ternary system known from metallurgy, consisting of gold, silver and copper (Au-Ag-Cu), to the effect pigment domain with the development of the Zenexo® Ternary System (ZTS) (YY-YS-OO).3 With the individual effect pigments GoldenShine (YY), GoldenWhite (YS) or CopperGlow (OO), it is possible to implement color shades in liquid and powder coatings, printing inks, or masterbatch and plastics previously known only from (semi-) precious metals (Figure 1). The new effect pigments have exceptional properties and their application profile allows new accents to be set in terms of color saturation, hiding power and color gamut in the mentioned applications.3

FIGURE 1 ǀ Left: Scheme of the ternary system based on metallic gold, silver and copper.4 Right: With the individual effect pigments GoldenShine (YY), GoldenWhite (YS) or CopperGlow (OO), it is possible to realize color shades in liquid and powder coatings, printing inks and plastic applications that were previously only known from (semi-) precious metals.

Particle Properties and Advantages

In our innovation process, we focused on the development of effect pigments with optimum hiding power, safety and improved coloristic properties. This work resulted in UTP technology.5 The newly developed pigments provide excellent opacity in comparison to state-of-the-art pigments of comparable particle size. We reduced the thickness of the aluminum substrate from 200 – 500 nm (typical for silver dollar flakes) to 20 nm. These particles are processed in a specific technology to achieve an average particle size of around 21µm, resulting in an outstanding aspect ratio not achievable before. UTP particles are coated with silica dioxide and iron oxide. The thickness of the iron oxide determines the color of the final pigment. A very thin layer results in a silver with a yellowish tint, next is a golden color and, if the thickness increases even more, the color turns orange.

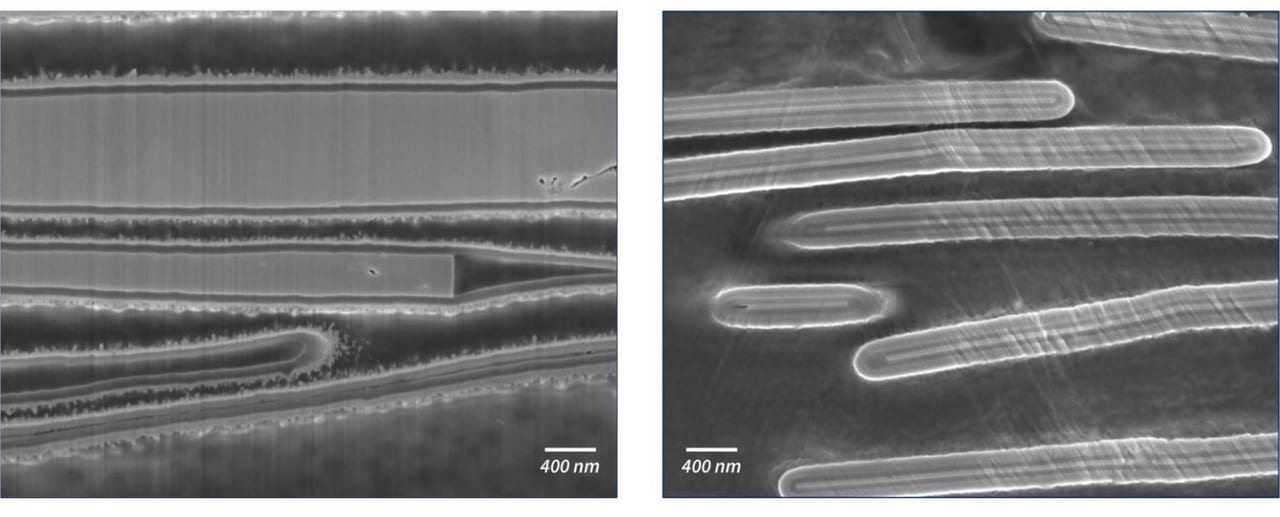

On microscopic observation of the particles, the geometry of the UTP-based effect pigment particles shows a reproducible and controllable particle thickness, which is significantly thinner than that of conventional metal interference pigments (Figure 2). This leads to a steep increase in aspect ratio, which is important for good flop expression.

FIGURE 2 ǀ Cross-section through conventional metal interference pigments (left) and through the new generation based on UTP-Technology (right).

Coloristic Evaluation

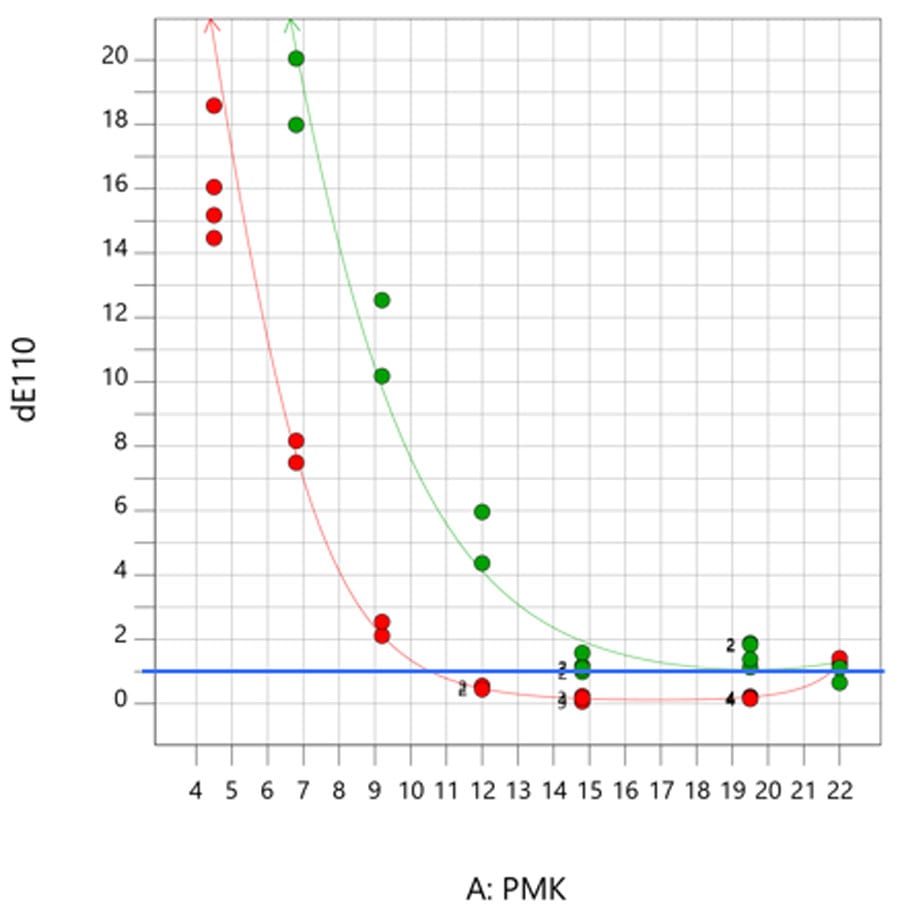

Evaluations of the hiding power of a 14-µm thick coating at different pigment mass concentrations show that the UTP-based pigment needs only a pigment mass concentration of around 10.5% instead of 18% for competing pigment technology in copper color (Figure 3). The other two new pigments in the UTP portfolio also deliver a significantly improved hiding power compared to state-of-the-art technology. Therefore, lower loading of pigment in a coating is possible or the coating thickness can be reduced with the same loading.

FIGURE 3 ǀ Evaluation of the hiding power of orange pigments at different pigment mass concentrations (PMK): Green: state of the art; Red: ultra-thin pigment technology. The blue line indicates hiding (dE110° below 1).

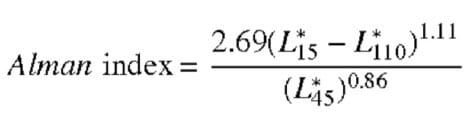

One outstanding property, in particular, of metallic surfaces and their imitations is color flop or travel. For a better comparison, we tested state-of-the-art metallic interference pigments with copper and gold colors. Due to the lack of silver-colored metallic interference pigments, a commercial aluminum pigment was used. These three pigments were compared with the new ternary system. All pigments were spray-coated at a film thickness of 14 µm and at a concentration where hiding power is reached. The lightness values are measured with a BYK-mac “i” metallic color multi-angle spectrophotometer. The Alman flop index (FI) is defined as

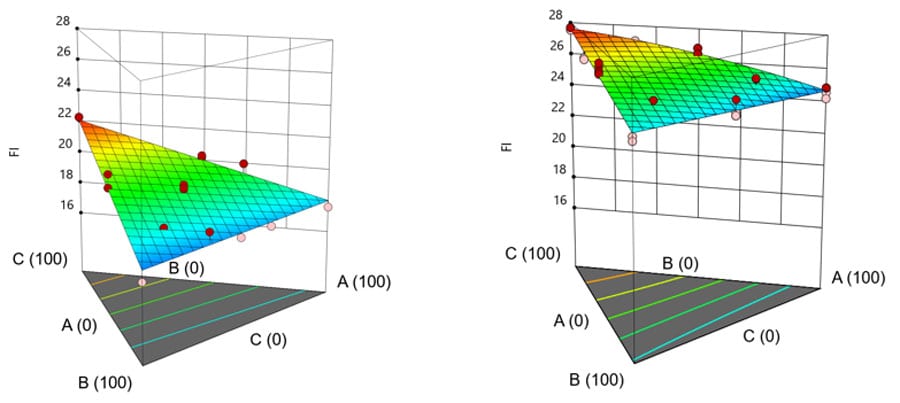

When calculating the Alman index for the colors created within the ternary system ZTS, a significant improvement of up to six units for gold colors using (YY) can be attained (Figure 4). For the copper pigment (OO) the difference to the state-of-the-art technology is even more pronounced.

FIGURE 4 ǀ Diagram showing flop indices of pigment mixtures using the cornerstone pigments YY-YS-OO at hiding concentration (A: silver-color, B: copper-color, C: gold-color). Left: state-of-the-art pigments, right: pigments based on new UTP Technology (ZTS).

Delivery Form

The delivery form of the new UTP pigments based on aluminum is a powder and no longer a solvent paste, which offers many advantages. For example, it is no longer an issue with the drying time of solvents that are delivered with the pigment and do not match with the formula of the paint. Formulations of 100% waterborne systems are possible, as well as the easier formulation of modern ultra-high solids. The absence of solvent makes dosing more precise. The solvent-free delivery form is possible because the pigment shows no dust explosion and is categorized as a non-hazardous good.

Application

The new pigment technology can be used for paint applications ranging from automotive products to architectural components such as facades (Figure 5), entertainment electronics, and everyday objects. The good news for the producer of powder coatings and masterbatch/plastics is that they no longer have to live without hiding color effects (Figure 6). The new pigments can be used in these applications due to the absence of solvents.

FIGURE 5 ǀ Coil coating facade with the new gold pigment shows a pronounced color travel/flop.

FIGURE 6 ǀ Powder coating application. Left: Comparison of ultra-thin pigment technology (5%, dry blend, left) vs. mica-based pearlescent technology (16%, bonded, right). Right: Chromatic stylings on door handles using pigments based on ultra-thin pigment technology.

To prove the progress in pigment technology, we replaced one stripe of genuine gold on a Rosenthal® cup with a stripe of UTP Technology gold (Figure 7). Even experts needed some time to find out the “replacement”.

FIGURE 7 ǀ Rosenthal® cup with stripes of genuine gold. one stripe is replaced with a printed stripe containing the new golden pigment (YY) based on UTP technology.

Summary

The major advantages of the pigments based on the new UTP technology can be summarized as follows:

- UTP allows the production of ultra-thin metal interference pigments;

- This class of pigment is now available for the first time in powder form and does not require hazardous-substance labeling;

- The new pigments have outstanding hiding power;

- They exhibit high gloss and are characterized by unprecedented flop;

- The three pigments GoldenShine (YY), GoldenWhite (YS) AND CopperGlow (OO) open a broad color gamut;

- The Zenexo Ternary System (ZTS) allows the convenient imitation of Au-Ag-Cu alloys.

Acknowledgment

The authors would like to thank Dr. Ralf Webler for his analytical support.

References

¹ Magnus, A. De mineralibus. Cologne 1569.

² Huber, A.; Maile, F.J.; European Coatings Journal, 03 2021.

³ Maile, F.J.; Schulze, J.; Lindner, J. Journal für Oberflächentechnik (JOT), 8 2021.

⁴ Degussa AG: Edelmetalltaschenbuch. Frankfurt 1967.

⁵ Shimizu, K.; Piech, F.; Huber A. Patent EP283280, 2013.