Advanced Polymer Strategies

for Enhancing Performance

of Water-Based Exterior Coatings

–Credit: Eliot76 / iStock via Getty Images Plus–

By Neal Rogers, Vinavil Americas

Polymers used to formulate modern exterior decorative coatings must meet performance challenges arising from exposure to a broad range of environmental conditions. Environmental factors that impact architectural coatings include temperature extremes, sunlight, wind and air quality. Exterior paint must be hard yet flexible, give strong dirt pickup resistance, maintain color and gloss uniformity, and produce strong water barrier performance. These challenges are magnified considering limitations to design polymers that allow formulated coatings to meet regulatory requirements. Additionally, consumers demand coatings that have low environmental impact and elevate performance compared to prior generations of technology.

Emulsion polymerization techniques have evolved to give numerous approaches to meet the exposure challenges of water-based exterior coatings. Designing polymer systems with optimized polymer morphology and structure allows coating formulators to develop higher performance exterior paints. In the following discussion, essential design features of emulsion polymers are considered to maximize performance of exterior decorative paints.

Influence of VOC Regulations on Acrylic Latex Polymer Design

Changing environmental regulations have shaped the evolution of exterior coating formulations. California Air Resources Board (CARB) began publishing rules for field-applied coatings starting with suggested control measure limits first adopted in 1989.¹ A listing of the evolution of CARB standards is shown in Table 1. Increasingly stricter VOC (volatile organic compound) regulations have altered coalescent usage and driven coatings formulas to lower VOC levels. Through the years, additional regions or local governments in the United States have cited the CARB standards to adopt their own VOC restrictions.

TABLE 1–ǀ–Evolution of CARB suggested VOC control limits for architectural coatings. All values in [g/L].

X

![Evolution of CARB suggested VOC control limits for architectural coatings. All values in [g/L].](https://cdn.vev.design/private/RxeA9TI6WxduOyIe0VDMVbrlpK92/image/x2pllspqZy_2jm6e7.svg)

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

Coalescents used for coatings formulated with emulsion polymers such as the commonly used 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and various glycol ether solvents are classified as VOCs by regional regulatory definitions. With the move to lower VOC levels, emulsion polymerization techniques had to be modernized to create polymers that performed with minimal coalescent requirements. However, the new polymers still had to deliver key performance attributes for exterior coatings. Polymer scientists have worked to develop and produce polymers that give hard yet flexible coatings and achieve a strong, uniform film while maintaining a low VOC.

Key Exterior Performance Criteria

Preserving physical appearance features such as gloss and color are key for performance of an exterior decorative coating system. Interactions between the polymer-based binder and pigments at the coating surface determine the overall gloss and appearance of the coating. Thermoplastic acrylic polymers are UV resistant, but variations in performance are possible. Initial surface uniformity and roughness, efficiency of coalescence and degree of crosslinking are coating attributes that determine the rate of deterioration of an exterior coating caused by sunlight, rain, snow or ice, and wind exposures.

Considering the traditional film coalescence model of a neat emulsion polymer latex, as water evaporates from the system, latex polymer particles pack closely together. The particles deform and gradually lose their morphology as the once distinct surfactant layers are compressed and a film is formed.² By considering a complete coating formulation containing both pigment and polymeric binder, characteristics of latex particle flow and the ability to fully wet pigment surfaces impact film formation. Higher amounts of coalescents and glycol solvents used with early emulsion polymers assisted the wetting and flow aspects. In contrast, modern acrylic emulsion polymers must perform without these materials to maintain a low VOC level.

Another aspect of polymer latex design that plays a role in gloss and color retention is the presence and speed of polymer crosslinking. A slow or limited crosslink leaves a film vulnerable to attack from early water and weather effects. On the other hand, a rapid crosslink could lead to cracking or other barely visible film defects that result in microcracks that depress gloss potential or the ability to maintain gloss over time.

ADVERTISEMENT

Dirt pickup resistance is another important feature of exterior coatings. Physical and chemical makeup of the coating surface impacts how dirt and pollutants interact with the coating. Important variables affecting dirt pickup resistance include surface film composition, tackiness, surface hardness, surface wettability, porosity and roughness.³ The latex polymer is a significant contributor to these surface characteristics with attributes such as the monomers used, the overall Tg of the system, and the latex particle morphology and structural shape.

Exterior coatings must also have a combination of hardness and flexibility to give the best performance potential. A harder finish supports surface durability, dirt pickup resistance, and mar and abrasion resistance. Flexibility of the coating film allows for use on unstable surfaces such as natural wood, the ability to bridge cracks in a substrate or between contrasting building materials and to resist degradation coming from coating embrittlement after weathering. A major challenge with low-VOC decorative paints is maintaining hardness in deep tint base dark colors when large amounts of colorants are added. Polymers have evolved to be generally softer to formulate paints with low coalescent demand. These already soft polymers are plasticized further from ingredients used in pigment dispersion colorants added at a high level — up to 10% by volume of the total tinted paint for dark colors. Without a carefully designed polymer system, deep tint colors have a soft and yielding tactile effect and are prone to collecting dirt or having poor gouge and imprint resistance.

Polymer Design Techniques to Maximize Exterior Durability

There are several technical approaches used in emulsion polymerization and latex design that allow polymers to achieve excellent performance for exterior coatings. One approach is forming a single latex polymer by combining multiple polymer phases during emulsion polymerization. Rather than cold blending two distinct polymer dispersions, incorporating two polymer domains into a single latex particle allows the coating to maintain different polymer attributes during the film formation process. Often, multiphase polymers utilize domains of contrasting hardness. Another approach is for the placement of functional monomers in precise locations of a polymer chain to promote specific environmental interactions.

Without a carefully designed polymer system, deep tint colors have a soft and yielding tactile effect and are prone to collecting dirt or having poor gouge and imprint resistance.

Multiphase latex polymers may consist of a distinct core-shell model⁴, such as a hard core with soft shell, so the soft polymer phase dominates in film formation allowing low coalescent usage. Variations of the core-shell model include a more gradual transition forming a gradient particle morphology or a lobed structure. When properly designed, dual polymer systems have potential to deliver the best of two separate polymers in a single polymer latex. For instance, the hardness of a high-Tg polymer with flexibility of low Tg is well suited for the multiphase emulsion polymerization technique.⁵ Other hybrid polymers explore different technology combinations such as chemical resistance of an epoxy with UV durability of an acrylic or weathering resistance of silicone with paintability of a polyurethane or acrylic.

Another emulsion polymer design attribute that influences exterior coating performance is forming latex in a nanoparticle size range. Nanoparticle size emulsion polymers are produced through a combination of polymerization technique and surfactant selection to minimize the particle size in a stable dispersion. Latex emulsions considered to have a nanoparticle size typically have a maximum 100 nm average particle size. Compared to traditional latex emulsions with average particle size of 140 nm or higher, the nanoparticle size emulsions are more transparent and give improved film formation characteristics. They also have higher penetration capacity that can assist with adhesion to porous substrates and an elevated surface functionality.⁶ The high surface functionality allows increased efficiency of additives that interface with latex particles prior to film formation.

Functionalization of an acrylic polymer emulsion imparts special properties to a formulated coating. Using specific functional monomers can give adhesion on metallic surfaces, convey hydrophobicity or hydrophilicity to the surface, impart reactivity to specific substances for desired interactions or provide locational crosslinking within the polymer. Crosslinking is the formation of a polymer network, based on the reaction of functionality present on the polymer chain, catalyzed by pH variations, UV light, heat, or solvent or water evaporation. Crosslinking is employed in polymer design to bring enhanced mechanical properties or resistance to water and chemicals that are present in the usage environment. Polymers can be designed so crosslink reactions occur either during polymerization stage or while the polymer is curing during or after film formation. The location of crosslinking reactive sites within the polymer chain affects the film morphology that is obtained for a finished coating.⁵

When properly designed, dual polymer systems have potential to deliver the best of two separate polymers in a single polymer latex.

Common crosslinking mechanisms used in acrylic emulsions for water-based coatings include metal complexes involving chelation of polyvalent metal ions with carboxyl groups.⁷ This type of metal complex crosslinking is often used in maintenance finish coatings for high-foot-traffic commercial floors. The keto-dihydrazide/diamine crosslink reaction is commonly used in decorative coatings to build surface hardness and toughness with an otherwise soft polymer. In another crosslinking approach, embedded UV crosslinking monomer activated by natural sunlight is a strategy sometimes used for polymers intended for elastomeric roof coating applications.

Specifying polymerizable surfactants for emulsion polymerization is a modern technical approach that can be used to functionalize polymers and enhance their performance in exterior coatings. Polymerizable surfactants covalently bond directly to the polymer backbone and have hydrophilic portions that support the emulsion micelle structure during synthesis.⁸ Conventional anionic and nonionic surfactants give electrostatic or steric stabilization to hydrophobic monomers during polymerization but are not chemically bound to the polymer.

Polymerizable surfactants can have as much as 40% or more of their content bonded with the polymer backbone after polymerization. Because the surfactant is bound to the polymer, this gives unique properties to an exterior coating such as improved water repellency, enhanced surface properties and blister resistance. The use of polymerizable surfactant often reduces hydrophilic materials that migrate through the aqueous phase of the coating. A high concentration of aqueous phase salts or other compounds that are unbound in a coating formula can lead to unfavorable surfactant staining or streaking on an exterior vertical wall coating.

Exterior Coating Performance Using Different Emulsion Polymer Design Techniques

Four different 100% acrylic polymer latex systems have been selected to demonstrate performance impacts of varying polymer design techniques on exterior coating performance. Each polymer has been placed in various coating systems and evaluated for properties depending on their target application. The polymers and their descriptions are found in Table 2.

TABLE 2–ǀ–Descriptions of four 100% acrylic latex polymers formulated using distinct design techniques and evaluated for exterior coating performance.

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

Polymer A gives an example of a multiphase nanoparticle size latex system. This polymer may be used in exterior wood coatings, a topcoat for composite substrates or for low-VOC metal coating. Polymer A has hard polymer domains with Tg above +100 °C and soft polymer domains with Tg below 0 °C, though its overall MFFT is approximately +10 °C. Typical average particle size for Polymer A is approximately 50 nm.

The morphology of Polymer A delivers a balance of hardness and flexibility to coating films. Polymer A is quite flexible, with a 500 µm film of Polymer A measured to have an elongation greater than 300%. In addition to the flexibility of the polymer film, a simple clear wood coating made from Polymer A has Persoz pendulum hardness of 130 cycles and gives a very good rating for elevated temperature block resistance. In combination with its particle morphology, the small average particle size of Polymer A imparts unique characteristics to a coating. It is suitable for porous substrates such as exterior wood that are subject to expansion and contraction with moisture and temperature changes. Its moderate MFFT of +10 °C allows it to formulate in other coating applications such as low-VOC metal coatings with good adhesion across different types of metal surfaces.

Polymer B has a unique characteristic, having among the smallest average particle sizes coming from a commercial emulsion polymerization process. The combination of processing technique and surfactant selection gives a stable dispersion with average particle size around 30–40 nm. Polymer B is used as a primer treatment for concrete or mineral substrates prior to applying a topcoat.

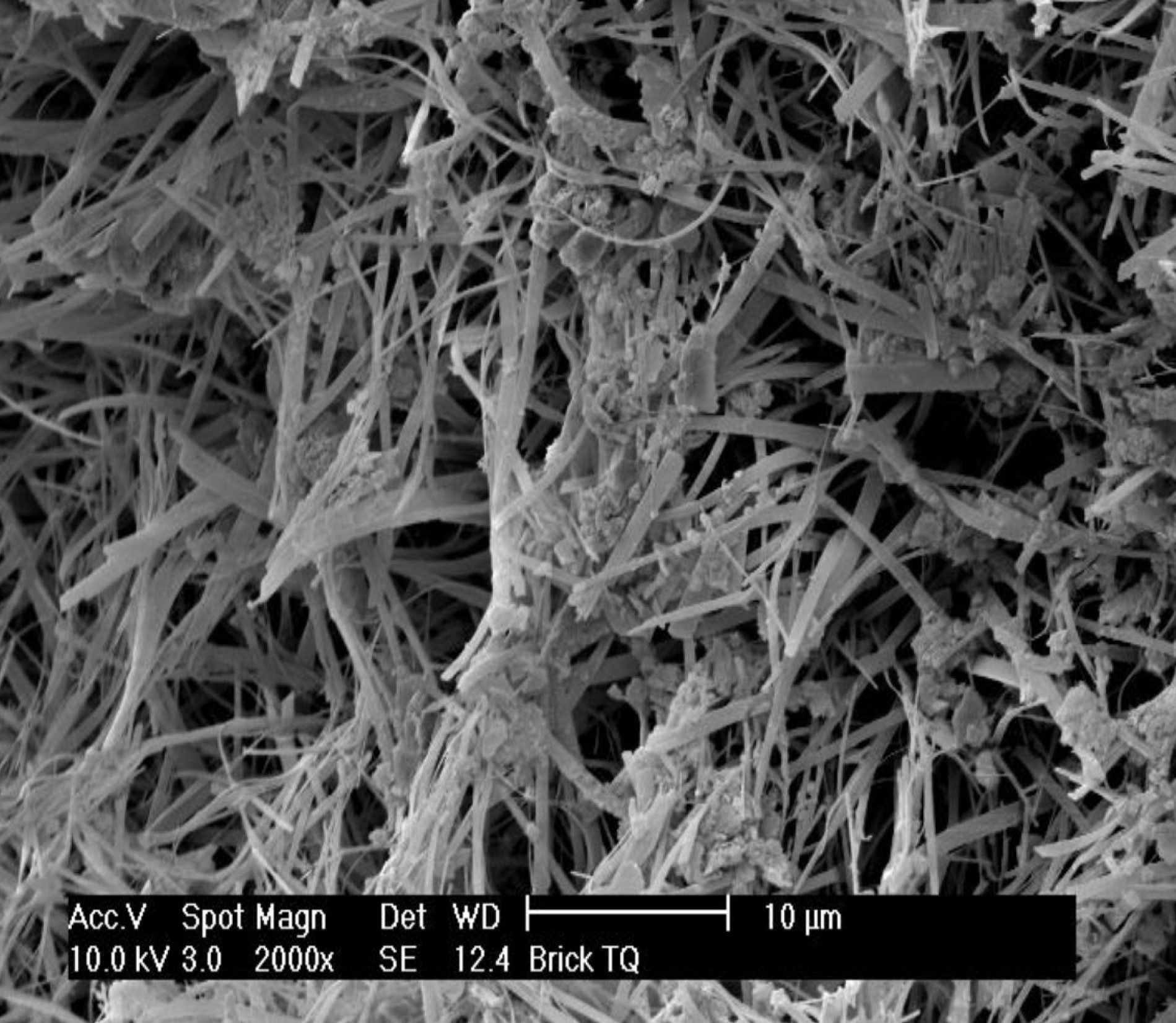

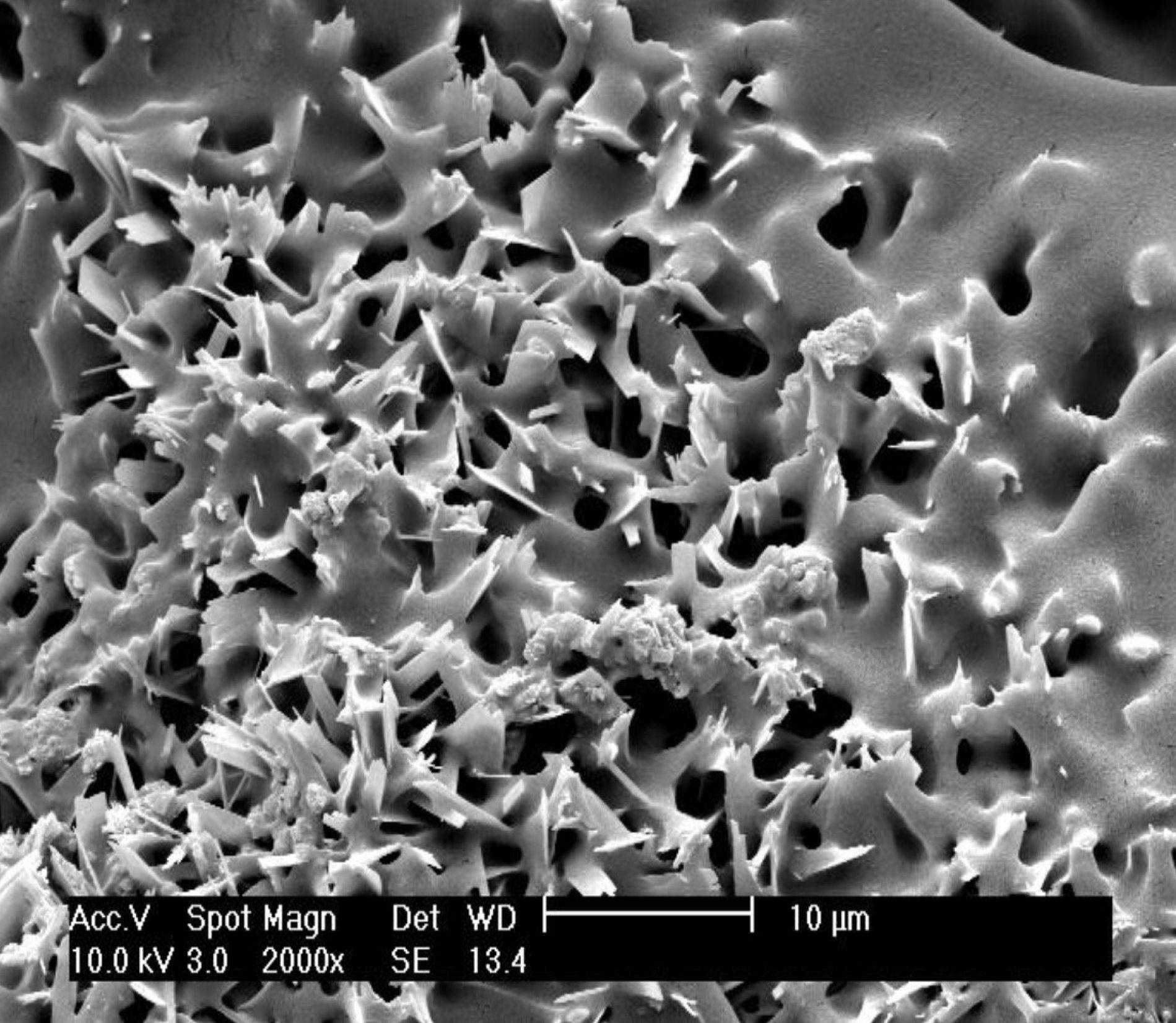

To demonstrate the substrate interaction of Polymer B, a filamentous mineral substrate was coated with a primer from Polymer B as depicted in Figure 1. The primer formulation is simply a 50% dilution of Polymer B with small amounts of defoamer and biocide added. The microscopic image of the substrate shows a network of open fibrous filaments. After the primer coat treatment is applied, many of the fibers are coated yet there is still a network of open space within the substrate. The fibers have been protected by the acrylic polymer, but the substrate maintains its breathability. In contrast, a primer made from latex polymer of a more typical particle size of 120 nm or larger is expected to fully block and obstruct all the pores in this substrate type and function only as a surface treatment.

FIGURE 1–ǀ–Microscopic image of filamentous substrate before and after treatment with Polymer B. Top image is untreated substrate; bottom image is coated with 50% dilution of Polymer B.

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

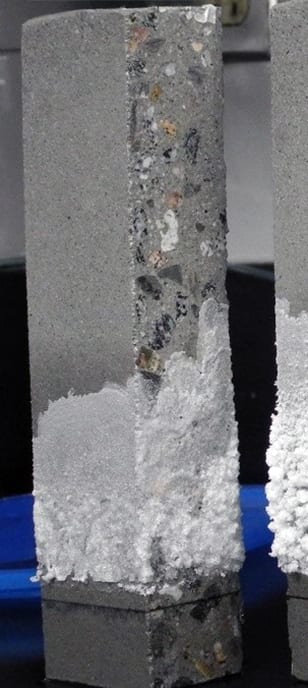

The benefit of small particle size from Polymer B can be demonstrated by the suppression of efflorescence resistance on cementitious surfaces. One method to visualize the impact of small particle size latex is through accelerated efflorescence testing. ASTM C67, Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile (American Society for Testing and Materials, C67/C67M-24, 2024), describes a procedure to measure efflorescence deposits from within a concrete block on the block’s surface. Water is allowed several days to wick into the concrete block, and salts naturally present in the concrete migrate and deposit on the surface. Modifying the test by placing coated blocks in a salt solution allows extra salt to flow through the block and deposit at the surface, accentuating the efflorescence effect.

Figure 2 depicts three different polymer types evaluated in a laboratory efflorescence demonstration following the described procedure. Two of the three polymers are acrylic latex of different particle size, and the third is a solvent-based solution polymer. The solution polymer type was chosen for comparison because it has long been used in concrete treatments and coatings for its ability to penetrate deeply, give a glossy appearance and to block salt migration. The largest efflorescence deposits are seen with the 150 nm average particle size latex polymer. Much less salt is deposited on the block sealed with Polymer B, the 35 nm average particle size latex. This observation is attributed to the penetration capability of the smaller particle size material combined with its characteristic efficient wetting of the filaments within the substrate. Polymer B gives a much closer performance to the solvent-based solution polymer.

FIGURE 2–ǀ–Relative efflorescence performance of two acrylic latex polymers of varying particle size and one solvent-based solution polymer.

Particle size 150 nm

REVERSE PINCH TO ZOOM

PolymerB, 35 nm

REVERSE PINCH TO ZOOM

Solution Polymer

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

Polymer C is an acrylic latex used for traditional semigloss or gloss interior and exterior decorative finish paints. Polymer C differs from the multiphase morphology of Polymer A because of its more distinct core-shell morphology. The difference in Tg between hard and soft polymer domains in Polymer C is 55 °C significantly smaller than the Tg difference between phases of Polymer A. Its core-shell structure allows coatings made from Polymer C to have good block resistance yet retain the ability to form a film with low levels of coalescent in formulation.

Table 3 shows a generic white gloss house paint formula reference using Polymer C that was evaluated for various architectural coating properties. This formulation developed gloss of 78 units at 60° viewing angle. Crosshatch tape adhesion showed no significant film removal over wood, aged alkyd, steel and galvanized metal panels. This paint also gave excellent elevated temperature block resistance evaluated at 50 °C. To demonstrate exterior exposure potential, the Polymer C-based paint was placed in a Xenon Arc accelerated weathering chamber and compared with three commercial paints — one solvent-based alkyd paint and two water-based latex paints.

TABLE 3–ǀ–White gloss paint from Polymer C.

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

Figure 3 highlights the gloss retention results over 600 hours of exposure time. The paint from Polymer C had the best gloss retention of these paints with a 600-hour gloss retention of 88% compared to a maximum of 62% gloss retained for the other paints.

The final polymer type explored in this discussion uses a polymerizable surfactant as the main surfactant in the emulsion polymerization process. This example is represented as Polymer D. The polymerizable surfactant use in Polymer D gives this material a low surface free energy. Surface free energy determines how a solid behaves when in contact with liquids. A low surface free energy of a polymer film generally indicates a liquid will have a more difficult time wetting the solid surface of the polymer.⁹ Coatings made from Polymer D deliver properties to an exterior coating such as improved water repellency, enhanced dirt pickup and blister resistance, and reduction of hydrophilic materials migrating in the aqueous phase. The latter results in improvement of surfactant staining or visible streaking for an exterior vertical wall coating.

FIGURE 3–ǀ–Gloss retention over 600 hours exposure in Xenon Arc weatherometer test.

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

A demonstration of the benefit of Polymer D is seen by formulating the material as the binder in a coating above critical pigment volume concentration (CPVC). The dried film of a coating above CPVC is predominantly pigment and expected to have little resistance to scrubbing with a mild surfactant solution. Selecting a polymer that effectively binds the high pigment loading and prevents water from easily wetting the surface will allow the coating to remain protected from the light scrubbing action. Figure 4 shows scrub test results of Polymer D compared with two other acrylic polymers in an 80% PVC formulation. Polymer D scrubbed over 2.5 times longer than the closest comparison acrylic that was evaluated. In addition to its excellent pigment binding and scrub resistance, benefits of using Polymer D in an exterior coating formulation are a balance of water barrier properties and dirt pickup resistance.

FIGURE 4–ǀ–Wet scrub resistance for 80% PVC paint in accordance with DIN 53778.

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

X

REVERSE PINCH TO ZOOM

Conclusion

Four examples of acrylic latex polymers have been reviewed: multiphase polymer morphology, nanoparticle size latex, incorporation of self-crosslinking and use of polymerizable surfactants. These examples demonstrate how advanced polymerization techniques and composition design enhance performance of exterior coating systems. The design strategies used alone or in various combinations give potential to create exterior coating formulations realizing the highest possible performance. Attributes such as gloss and color retention during weathering, penetration, water resistance and dirt pickup resistance were enhanced while adhering to environmental regulations that limit coalescing agent and solvent amounts used in formulation. Selecting a polymer supplier experienced in harnessing the strengths of polymer design strategies can elevate coating formulations to achieve exceptional exterior durability and performance.

References

1 California Air Resources Board. Architectural Coatings Suggested Control Measures; California Environmental Protection Agency: Sacramento, CA, 2020.

2 Flack, Kyle; Foley, Nicholas; Vaughn, Tyrone; Kicklighter, Lisa; Mangano, John. Permanent Coalescent Choice in Low-VOC Architectural Paints. Presented at the 44th International Waterborne, High Solids and Powder Coating Symposium, New Orleans, LA, Feb 22–24, 2017.

3 Brown, Scott C.; Diebold, Michael; Kraiter, Daniel; Velez, Carlos; Jernakoff, Peter.Towards a Comprehensive Understanding of Dirt Pickup Resistance. CoatingsTech 2020, 17 (6), 14–27.

4 Stubbs, Jeffrey M.; Sundberg, Donald C. The Dynamics of Morphology Development in Multiphase Latex Particles. Prog. Org. Coat. 2008, 61 (2–4), 156–165.

5 Jiménez, Nerea; Ballard, Nicholas; Asua, José M. Hard Coatings from Soft Latexes: A Review of Routes to Overcome the Film Formation Dilemma. Macromol. Mater. Eng. 2024, 309 (9).

6 Schirò, Antonietta; Ballarati, Luca; Mader, Antonio; Cerra, Marco. Going Nano to Mimic Penetration of Solvent-Based Products. Paint Coat. Ind. 2018, 34 (3), 48–52.

7 Parvate, Sumit; Mahanwar, Prakash A. Advances in Self-Crosslinking of Acrylic Emulsion: What We Know and What We Would Like to Know. J. Dispers. Sci. Technol. 2018.

8 Palmer, Charles F., Jr. New Reactive Surfactants for Emulsion Polymerization. Presented at the 39th International Waterborne, High Solids and Powder Coating Symposium, New Orleans, LA, Feb 15–17, 2012.

9 Laurén, Susanna. What Is Surface Free Energy? Biolin Scientific Surface Science Blog, Jan 19, 2021.